What is wine jar – In-depth Guide to Skyrocket your Business

As fermentation and aging vessels, wine jar play a key role in many industries and applications. You can use them to make wine.

However, as a professional winemaker, choosing the best winemaking tools requires a clear understanding of your desired end result, the manufacturer or supplier’s capabilities, process characteristics, quality control, application, and maintenance.

This is precisely what we will explore today.

What are wine jars?

Wine jars, also known as the amphorae or terracotta jar, are porous clay vessels used for fermenting and aging wine.

Their constant temperature properties and design, which promotes natural convection, make them popular with natural winemakers seeking to express their terroir in its purest form.

Wine Jar Manufacturing and Supply Capabilities

Choosing a reliable wine jar supplier requires careful evaluation of several key factors:

Production Scale and Expertise:

● Assess the manufacturer’s experience with winemaking-specific vessels

● Evaluate their production capacity and ability to meet your timeline

● Review their portfolio of successful installations

● Verify their understanding of different wine styles and requirements

Technical Support and Service:

● Ensure comprehensive after-sales support

● Check availability of technical consultation

● Confirm provision of detailed usage guidelines

● Verify emergency support capabilities

Reputation and References:

● Seek references from existing clients

● Review case studies and success stories

● Assess industry reputation and longevity

● Evaluate commitment to research and development

Wine jar manufacturing process

Material Selection and Processing

Quality manufacturers use specific clay types sourced from proven deposits, carefully controlling their composition to ensure optimal porosity and mineral content. The clay is thoroughly purified and aged before molding.

Molding Techniques

While traditional hand-coiling techniques are still used to create handicrafts, modern manufacturers often combine these methods with slip casting or roll-forming techniques to achieve perfect wall thickness consistency and ensure predictable oxygen transfer rates.

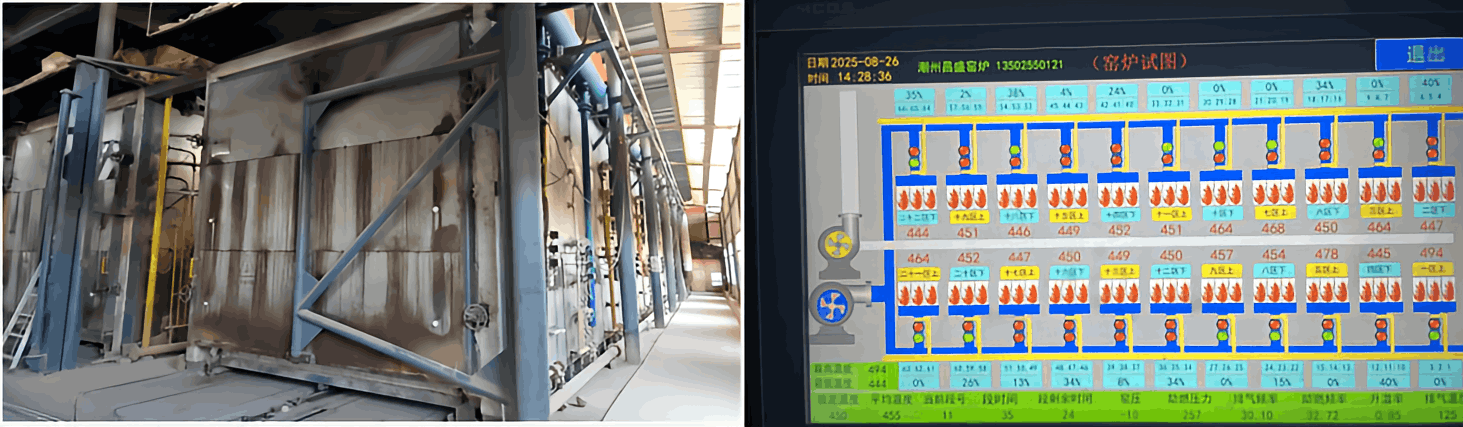

Firing Process

The firing stage takes place in a computer-controlled tunnel kiln at a precisely controlled temperature (typically 1200°C), which determines the ultimate porosity, strength, and longevity of each vessel.

Quality Control: Ensuring Consistent Performance In Wine Jars

Robust quality assurance measures are implemented to ensure container reliability:

Structural integrity testing:

● Pressure testing to identify microcracks

● Wall thickness is measured using a traditional tape measure (typically 2 cm)

Performance verification:

● Water absorption and lead, chromium, arsenic, and manganese testing

● Chemical composition analysis

● Qualified third-party testing reports

Wine Jars of Commercial Applications

Product Differentiation:

Wines aged in clay wine jars typically demonstrate unique textural qualities and flavor complexity that support premium pricing strategies.

Many wineries establish dedicated clay-aged wine lines that achieve 20-40% price premiums over their conventional counterparts.

Market Positioning:

Wine jars used for winemaking are typically unglazed, offering a distinct difference from oak barrel winemaking.

Winemaking in clay jars is more in line with future trends, resulting in wines that are purer and more expressive of their terroir, resonating well with wine lovers.

Production Advantages:

Beyond marketing benefits, these vessels offer tangible production benefits including reduced intervention requirements, natural stabilization, and the creation of distinctive house styles that competitors cannot easily replicate.

Maintenance and Operations: Ensuring the Long-Term Success of Wine Jar

Daily Operations:

Establish standardized protocols for filling, monitoring, and emptying processes. Implement detailed record-keeping systems to track each vessel’s performance and the evolution of its contents.

Cleaning and Sanitation:

Develop comprehensive cleaning procedures utilizing hot water, steam, and mechanical brushing systems. Implement strict drying protocols between uses to prevent microbial contamination.

Preventive Maintenance:

Conduct regular inspections for hairline cracks or surface degradation. Establish scheduled maintenance routines and maintain appropriate environmental conditions to ensure vessel longevity.

FAQ: Addressing Critical Business Questions

1. What is the typical ROI for investing in wine jars?

Most commercial operations achieve complete ROI within 2-3 vintages through a combination of premium pricing and production efficiencies. The 200-liter vessels typically generate positive returns within 18-24 months for wineries producing 500+ cases annually.

2.How does production scale affect implementation strategy?

For smaller operations (under 1,000 cases), we recommend starting with 2-3 smaller vessels (50-100L) for experimental lots and premium offerings. Larger wineries should consider phased implementation, beginning with a dedicated clay program for their premium tier before expanding.

3. What staffing requirements are necessary?

While specialized expertise is valuable, most skilled cellar workers can master clay vessel management with proper training. The key differentiator is developing a nuanced understanding of how clay interaction affects different varietals and wine styles.

4.How do clay jars integrate with existing equipment?

Modern clay wine jars are designed to fit seamlessly into contemporary winery workflows. They typically utilize standard fittings and can be incorporated alongside stainless steel tanks and oak barrels without significant facility modifications.

5. What marketing advantages do clay-aged wines offer?

Beyond the tangible quality differences, clay-aged wines provide compelling narrative elements including historical connection, artisan craftsmanship, and natural winemaking approaches. These stories typically generate strong media interest and consumer engagement.

Wine Jar Strategic Implementation Framework

Phase 1: Research and Planning (1-2 months)

● Conduct market analysis of clay-aged wine positioning

● Evaluate supplier options and technical capabilities

● Develop implementation budget and timeline

● Identify initial wine styles for clay experimentation

Phase 2: Initial Implementation (3-6 months)

● Procure initial vessels and necessary support equipment

● Train key staff in clay-specific techniques

● Launch first clay-aged wine projects

● Develop monitoring and evaluation systems

Phase 3: Expansion and Optimization (6-18 months)

● Analyze results and refine techniques

● Scale successful approaches across additional products

● Develop marketing materials and sales strategies

● Consider custom vessel configurations for specific needs

Conclusion

By carefully selecting partners, implementing robust processes, and developing a compelling market positioning, wineries can effectively leverage this ancient technique to create distinctive products and capture a premium market position.

For forward-thinking wineries, these vessels offer a proven path to producing exceptional wines that tell a compelling story while generating strong returns.

Customize Your Wine Jars for Your Wine Projects

As a professional manufacturer, the Hexin team is dedicated to customizing fermentation vessels specifically for your wine jar winemaking projects.

Contact our dedicated team today to learn more about our expertise and policies.