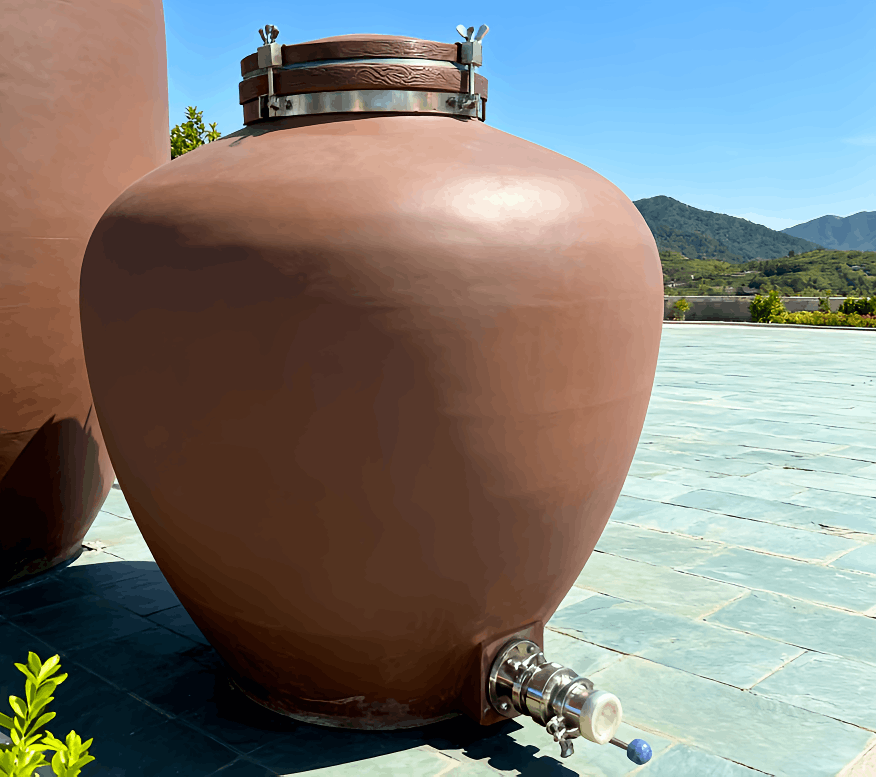

How to Customize Amphora Wine Vessel for Your Winery: A Manufacturer’s Guide

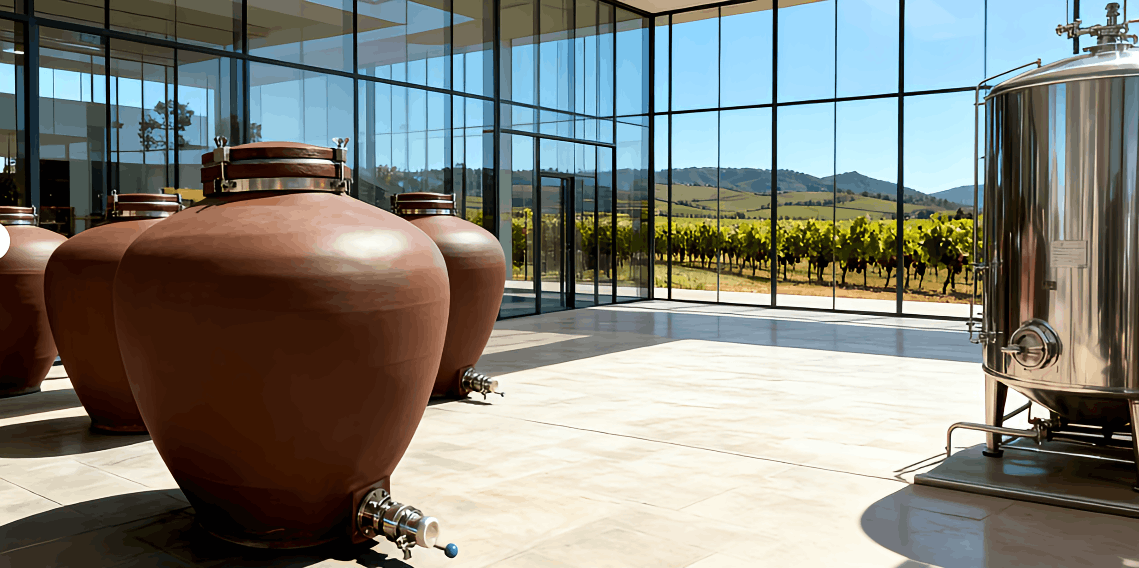

Amphora winemaking is increasingly popular among experienced wine enthusiasts and professional winemakers. Wineries worldwide are discovering the unique expressiveness of these ancient vessels.

As a result, amphora wine merchant are increasingly embracing and pursuing this ancient and unique vessel. However, the key question is how to customize an amphora to perfectly suit your specific winemaking philosophy and technical requirements.

Today, from the perspective of a professional manufacturer, we’ll explore how to create a unique amphora for any project. We’ll cover product positioning, features, advantages, manufacturing processes, and quality control (QC) FAQs, while also providing practical insights for working with experienced manufacturers.

Benefits of Customizing Amphora Wine Vessel for a Specific Project

Before undertaking customization, it’s crucial to clearly understand your overall amphora production strategy and brand positioning.

Market Differentiation:

● Provide high-end services for established wineries seeking to elevate their offerings

● Develop a signature style for emerging wineries building their market presence

● Provide a foundation for experimental projects for innovative wineries pushing boundaries

Production Integration:

Successful customization requires considering how these amphora products will fit within your existing ecosystem:

● Workflow compatibility with existing production processes

● Space optimization based on your specific facility layout

● Matching employee skills to ensure operational excellence

● Scalability planning to accommodate future growth and expansion

Amphora Wine Vessel The Customization Spectrum

Understanding the available customization parameters enables informed decision-making.

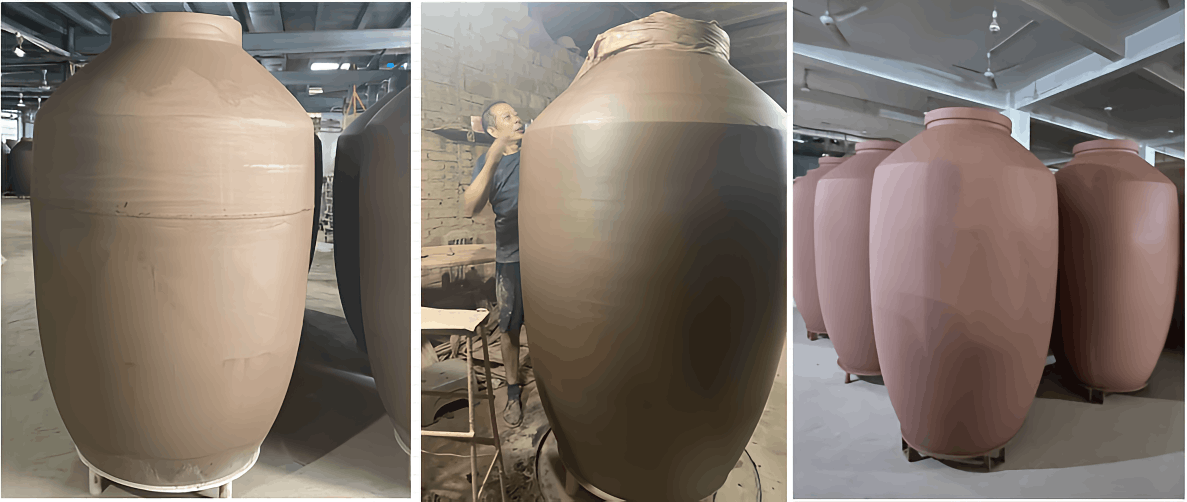

Shape and Process Customization:

● Shape Customization:Customize various shapes according to your drawings

● Color customization: through a selection of natural clays and manufacturing processes

● Personalized customization:Innovate forms while maintaining functional integrity

● OEM&ODM customization:Branding integration through subtle embossing or custom markings

Technical Specifications:

echnical Specifications: Optimize capacity based on production volume (50 to 2000 liters)

● Calibrate wall thickness for precise oxygen transfer management

● Specialized openings and access points for various winemaking processes

● Integrate accessories for modern monitoring and processing equipment

Competitive Advantages of Customized Solutions

The investment in customization delivers measurable returns across multiple business dimensions.

Quality Superiority:

● Wineries using purpose-built amphorae report:

● 18-25% higher critic scores for texture and complexity

● 30% faster integration and maturation for certain varieties

● Enhanced aromatic preservation and development

● Consistent performance across vintages

Operational Excellence:

● 25-40% reduction in handling time with ergonomic designs

● 30% longer vessel lifespan through optimized construction

● Reduced breakage and maintenance costs

● Streamlined cleaning and sanitation processes

Market Impact:

Customized vessels enable:

● Premium pricing strategies (15-30% price increases)

● Stronger brand storytelling and media coverage

● Direct consumer engagement through distinctive visuals

● Distribution advantage through unique product features

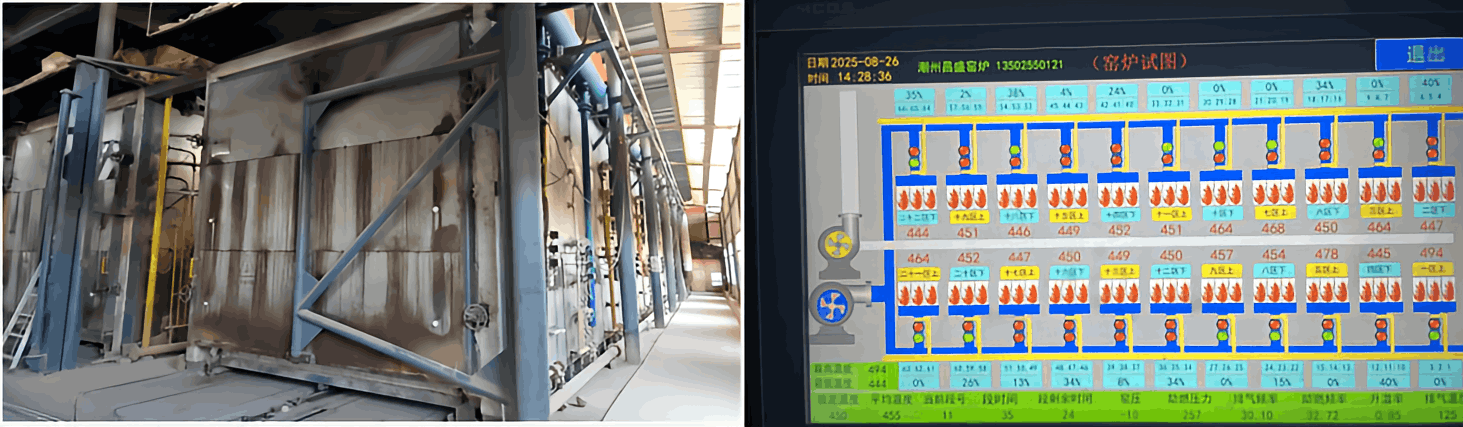

Advanced Manufacturing Process

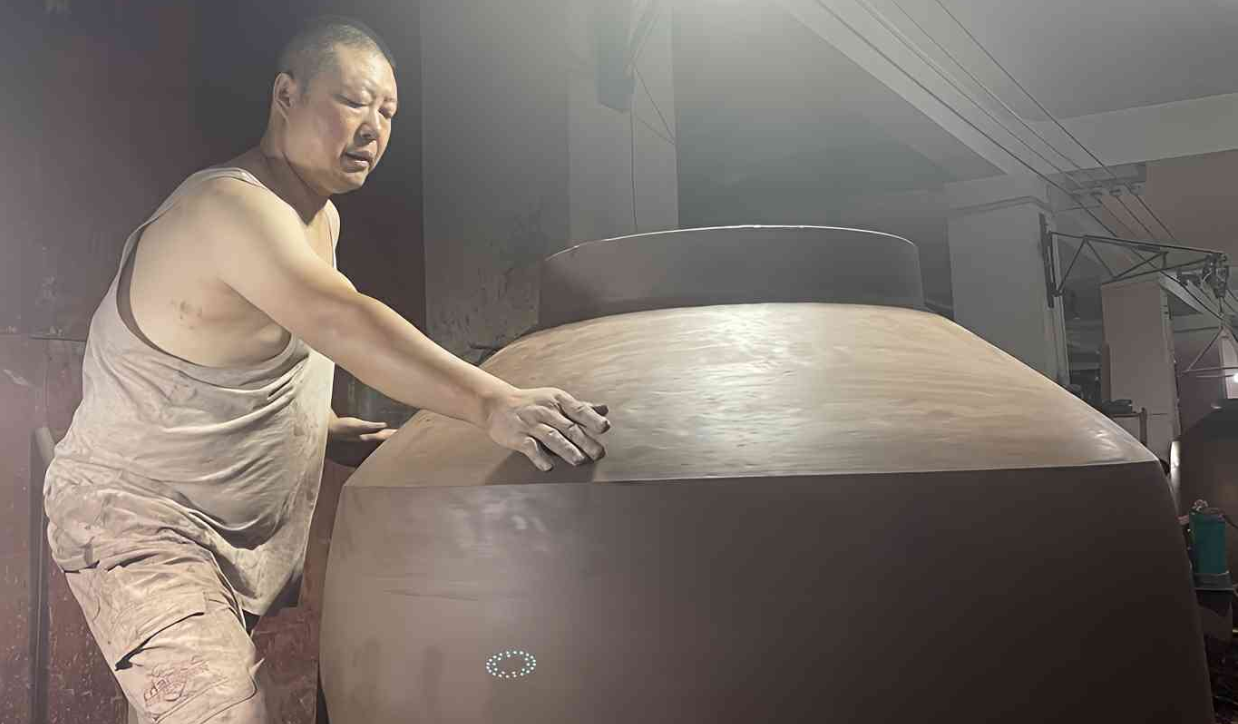

Our manufacturing methods seamlessly blend ancient craftsmanship with modern terracotta making process.

Material Science Selection:

● Natural clay sourced from specific natural mining areas

● Mineral composition analysis ensures predictable interaction between wine and raw materials

● Clay undergoes rigorous testing to ensure batch-to-batch consistency

Exquisite Manufacturing:

● Computer-controlled molding ensures precision and consistency

● Progressive kiln firing with precise temperature profile control

● High-temperature (1200°C) firing ensures strength, porosity, and breathability

Quality Control:

● Each vessel undergoes the following tests:

● Artisan-individually tested for thick walls

● Tested for water absorption, lead, chromium, arsenic, and manganese

● Structural integrity testing with accompanying test reports

Comprehensive Quality Control: Ensuring Consistent Performance

Our multi-stage QC process guarantees every vessel meets exacting standards.

Material Quality Control:

● Chemical analysis of incoming clay

● Verification of moisture content and purity

Production Quality Control:

● Daily dimensional accuracy inspection

● Molding process monitoring

● Drying environment control

● Firing cycle verification

Final Inspection:

● Visual inspection under controlled lighting

● Measurement verification according to specifications

● Strict water permeability testing

● Documentation and Certification (third-party testing report)

Manufacturing Partnership: Beyond Supplier Relationships

Choosing the right manufacturing partner helps your customization move from concept to reality.

Technical Collaboration:

We establish:

● Dedicated project teams with technical and winemaking expertise

● Regular progress reviews and milestone verification

● Transparent communication channels for quick decision-making

● Problem-solving partnerships throughout the process

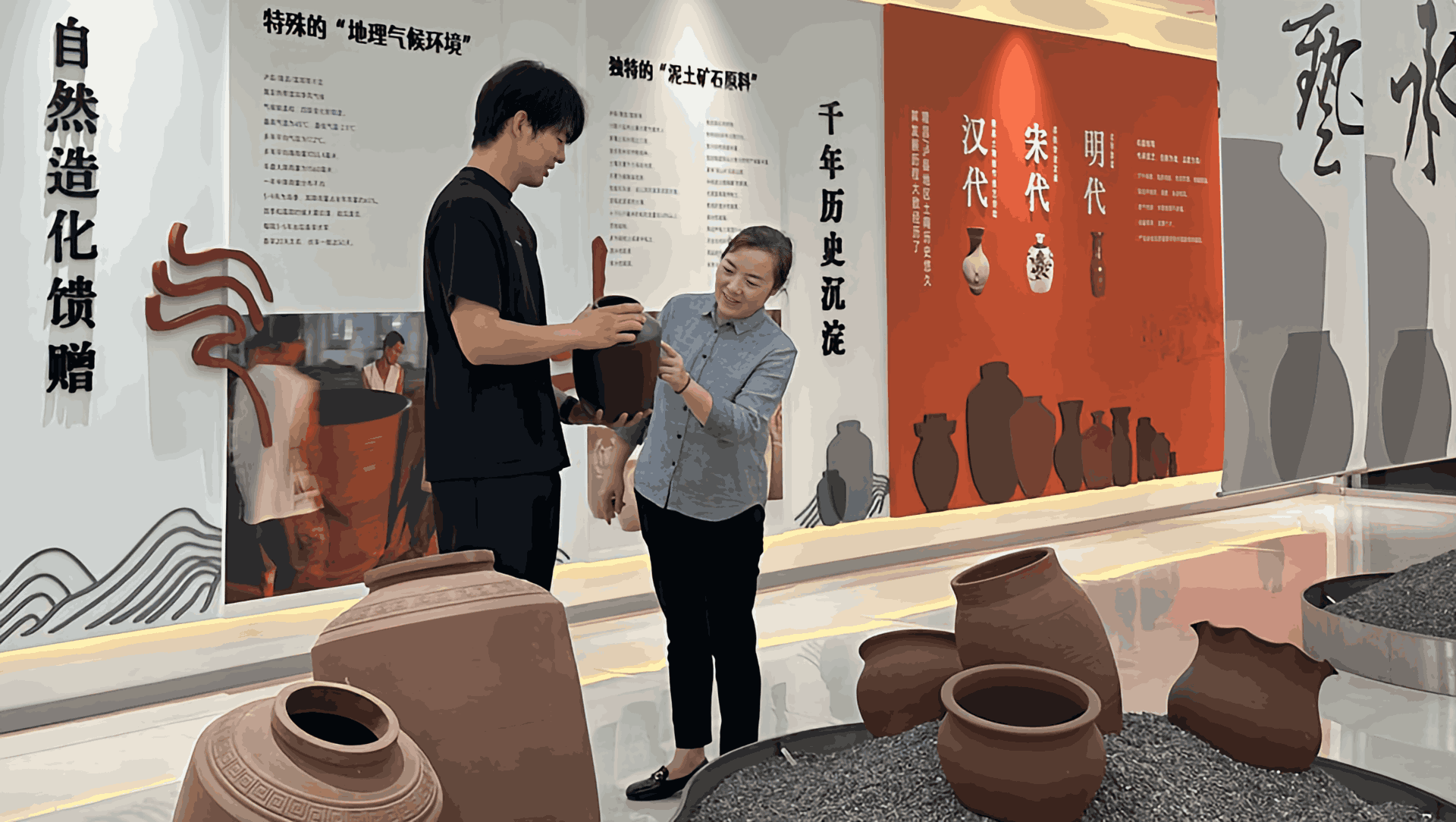

Industry Experience and Customization Capabilities:

Our track record includes:

● Over 200 successful customization projects with over 100 leading wineries

● Nearly 50 years of experience in the terracotta making process

● Continuous innovation in materials and manufacturing technologies

● Comprehensive support from concept to decades of use

FAQ: Addressing Critical Customization Concerns

1.What is the realistic timeline for custom amphora development?

Standard custom projects require 14-18 weeks from initial consultation to delivery. This includes: design finalization (2-3 weeks), prototype development (4-5 weeks), production (6-8 weeks), and quality verification (2 weeks). Complex innovations may extend this timeline.

2. How do you ensure design feasibility for winemaking functionality?

Our design team includes experienced winemakers who validate every custom design against practical winemaking requirements. We also create functional prototypes for client testing before full production.

3. What minimum order quantity is required for custom projects?

While we accommodate single-vessel custom orders, optimal pricing and manufacturing efficiency typically begins at 3-5 units. For completely new designs, we recommend starting with a prototype before committing to full production.

4. Can you replicate specific historical amphora designs with modern reliability?

Absolutely. Our research team has documented numerous historical designs, and we can faithfully reproduce them while incorporating modern structural integrity and food safety standards.

5.What technical support do you provide after delivery?

Our partnership includes comprehensive support: installation supervision, staff training, maintenance guidelines, and ongoing technical consultation. We remain available to help optimize your use of the vessels.

Transform your winemaking through strategic partnerships

Creating a perfectly customized amphora project is more than just a purchase of winemaking equipment,it’s an investment in the future differentiation and excellence of your winery.

Implementation Success Factors:

● Clear quality objectives and technical requirements

● Open collaboration with manufacturing partners

● Phased implementation approach

● Continuous evaluation and adjustment

Long-term Value Creation:

● Distinctive house style development

● Operational efficiency improvements

● Market positioning enhancement

● Quality consistency across vintages

Customize an Amphora Wine Vessel for Any Project

HEXIN is professional Amphora Wine Vessel manufacturer in China, dedicated to providing custom winemaking vessel solutions for wineries and professional winemakers. Handcrafted craftsmanship guarantees quality!

Contact our technical team now by filling out the form and we’ll respond within 24 hours.