Based on your initial intention, we will further deepen our understanding to accurately understand your specific needs and facilitate the smooth progress of subsequent work(We will do customization for you). It includes:

1. Functional requirements: Clearly define product usage and performance requirements, etc

2. Technical parameters: Clearly define size, capacity, device structure, surface treatment, color, etc

3. Compliance and Standards: Product testing reports, certifications, packaging, transportation, and acceptance standards, etc

4. Business terms: quantity and price, delivery time, and sample process communication

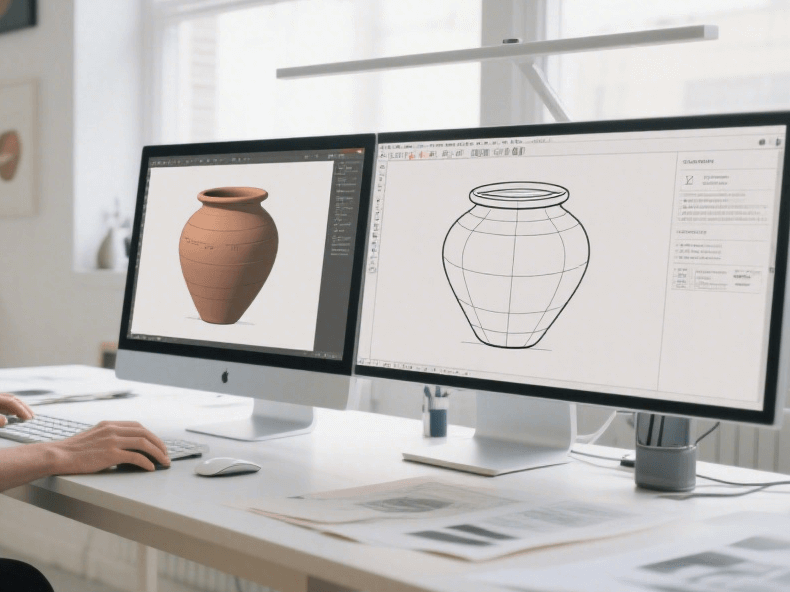

Design Proposal

After clarifying the specific requirements, our project team (R&D, design, technology) will design and confirm according to the customer’s specific needs or drawings(We will do customization for you). The following five steps are required:

- Technology conversion and feasibility analysis;

- Design output

- Internal review

- Delivery of the plan and confirmation with the client

- Freeze and archive the plan.

Mold Development

After the client confirms the design proposal draft, we will proceed with mold development based on the final plan. We will use gypsum molds to create the desired mold samples for the client(We will do customization for you). The usual mold development cycle is 4-8 weeks, which can be divided into the following stages:

- Mother Model Creation

- Casting the Plaster Molds

- Drying&Assembly of Molds

- Trial&Approval

Regarding mold development and production, please refer to the following schedule

| Mold Development Cycle | |||

| Phase | Core Mission | Estimated Time Required | Output And Milestones |

| Week 1 | Mold processing | 7-10 days | Complete the first sample of the mold and conduct internal inspection |

| Week 2-3 | Gypsum mold production | 5-7 days | Complete the production of a complete set of gypsum molds |

| Week 3-4 | Mold drying | 7-10 days | The mold has reached a usable level of dryness. (Critical waiting period) |

| Week 4-5 | First trial mold | 2-3 days | Produce the first trial sample and conduct internal measurements |

| Week 5-6 | Modification and secondary trial molding | (If needed) 3-5 days | Produce secondary samples. |

| Week 6-7 | Customer confirmation | 5-7 days | Send the sample to the customer and receive their signature. (Key milestones of the project) |

| Week 8 | Mold storage | 1 day | The mold has been officially delivered to the production department, and the development process has ended |

Sample Production

Once the mold is ready, we create initial samples to ensure the product meets your expectations. Our team meticulously monitors this process to verify quality and design, delivering samples for your final review and approval.

- Sample planning and preparation

- Sample production and firing

- Sample testing and confirmation.

Sample production timeline

Sample production is a process of “slow work, fine work” . Its standard cycle is usually 3-5 weeks. The specific time nodes are shown in the table below.

| Reference Table for Sample Production Time Cycle | |||

| Order | Phase | Estimated time required | Explanation and Key Points |

| 1 | Planning and Material Preparation | 3-5 working days | Complete internal review, issue ‘Sample Production Form’, and prepare clay glaze materials |

| 2 | Body production and drying | 7-10 days | This process is relatively slow |

| 3 | plain roasting | 3-4 days | Including the entire process of kiln installation, firing, cooling, and kiln discharge |

| 4 | Glazing | 1-2 days | |

| 5 | glaze firing | 4-5 days | After firing, it must be naturally cooled to room temperature, and opening the kiln is strictly prohibited |

| 6 | Kiln inspection and internal confirmation | 2-3 working days | Conduct a comprehensive inspection and issue a report |

| 7 | Delivery and customer confirmation | 7-10 days | Sending international express delivery time+customer internal review time |

| Total (ideal situation) | About 4-5 weeks | Excluding the repeated modification time during the customer confirmation phase | |

Mass Production

The mass production process refers to the entire manufacturing process of Terracotta jars(We will do customization for you). Its core goal is to efficiently complete order delivery while ensuring quality consistency. It follows the following production process steps:

- Raw material preparation and pretreatment;

- Body forming;

- Drying and demolding;

- Repair and bonding;

- Vegetarian burning;

- Enamel firing;

- Out of kiln, inspection and packaging;

Time nodes of mass production process

The production cycle depends on the number of orders, the complexity of the equipment shape, and the capacity of the kiln. The following is a reference schedule for a standard grouting molding process:

| Reference Schedule For Pottery Jar Forming And Manufacturing Process | |||

| Order | production Phase | Estimated Time Required | Condition Description |

| 1 | raw material preparation | 1-2 days | Pre treatment time for clay and glaze materials |

| 2 | casting | 2-3 days | Depending on the number of molds, multiple sets of molds can be used in parallel |

| 3 | Dry demolding | 2-5 days | The longest time consumption |

| 4 | Repairing and bonding of raw materials | 1-2 days | Dependent on the number and proficiency of workers |

| 5 | Drying and vegetarian cooking | 3-4 days | Including the entire process of kiln installation, firing, cooling, and kiln discharge |

| 6 | Glazing | 1 day | |

| 7 | glaze firing | 3-4 days | Including kiln loading, firing, slow cooling, and kiln discharge |

| 8 | Inspection and Packaging | 2-3 days | |

| Total (production cycle) | About 15-25 days | This is pure production time, excluding scheduling, holidays, etc | |

Quality Inspection

Our quality inspection is the final step in ensuring that customized Terracotta jars meet your requirements and standards. Our QC inspection standards and methods are as follows:

1. Appearance defects (100% full inspection)

Conduct a comprehensive inspection for cracks, deformations, glaze defects, and bottom treatment.

2. Physical performance (sampling destructive testing)

It is necessary to conduct two performance tests on the terracotta products, namely compressive strength and thermal shock, to ensure full compliance with the standards.

3. Safety testing (mandatory for each batch)

mainly conducting acid solution immersion testing to test whether the content of heavy metal ions in the solution exceeds the standard.

Pack And Ship

To ensure the safe delivery of orders and reassure customers, we follow the following operating standards and solutions:

1.Packaging and transportation meet the conditions:

Final inspection and cleaning(including product and document matching and full supervision and recording, while purchasing full transportation insurance.)

2. Packaging scheme

We use vibration imitation inflatable cushion protection products, and small terracotta cans such as terracotta bottles and terracotta jug and small terracotta storage jar use foam and thickened corrugated cartons.

3. Customized packaging solutions

Super large terracotta pot: we customize a fully closed wooden box or metal frame. The interior is completely closed with foam mold, which can be directly stacked and transported.

4. Regarding transportation plan

We support sea and land transportation. Specific transportation plans will be selected based on order quantity, delivery time, and cost budget, and appropriate transportation methods will be chosen. Please consult our sales team promptly for specific implementation.