What Is an Amphorae?

A Complete Guide to Amphora Winemaking, History, and Modern Use

Have you frequently encountered the term “amphora” while exploring the world of natural wines or low-intervention winemaking? It seems to always appear alongside fascinating concepts like “ancient techniques,” “orange wine,” and “terroir expression”—but what exactly is an amphora? Why is this seemingly museum-worthy object now appearing in the cellars of more and more pioneering wineries worldwide?

Simply put, an amphora is a container made of clay or terracotta that has been used for thousands of years to ferment, age, and store wine. But don’t imagine it as just a simple clay pot. In the hands of modern winemakers, it has evolved into a unique winemaking tool, particularly favored by those seeking ultimate purity, complex textures, and an authentic expression of the vineyard’s terroir.

In this guide, we will unveil the mystery of the amphora. You will learn about its rich history, its crucial role in winemaking, and why it is experiencing a resurgence today—it’s far more than just a retro trend, both from a cultural heritage and winemaking science perspective.

What are Amphorae?

The amphora, a term often associated with “natural wine” and “ancient techniques,” what exactly is it? Far from being merely a nostalgic symbol, it’s a sophisticated winemaking vessel that blends millennia of wisdom with modern craftsmanship.

To understand why amphorae are unique, the key lies in their three core characteristics: material, shape, and the distinctive winemaking effects they produce.

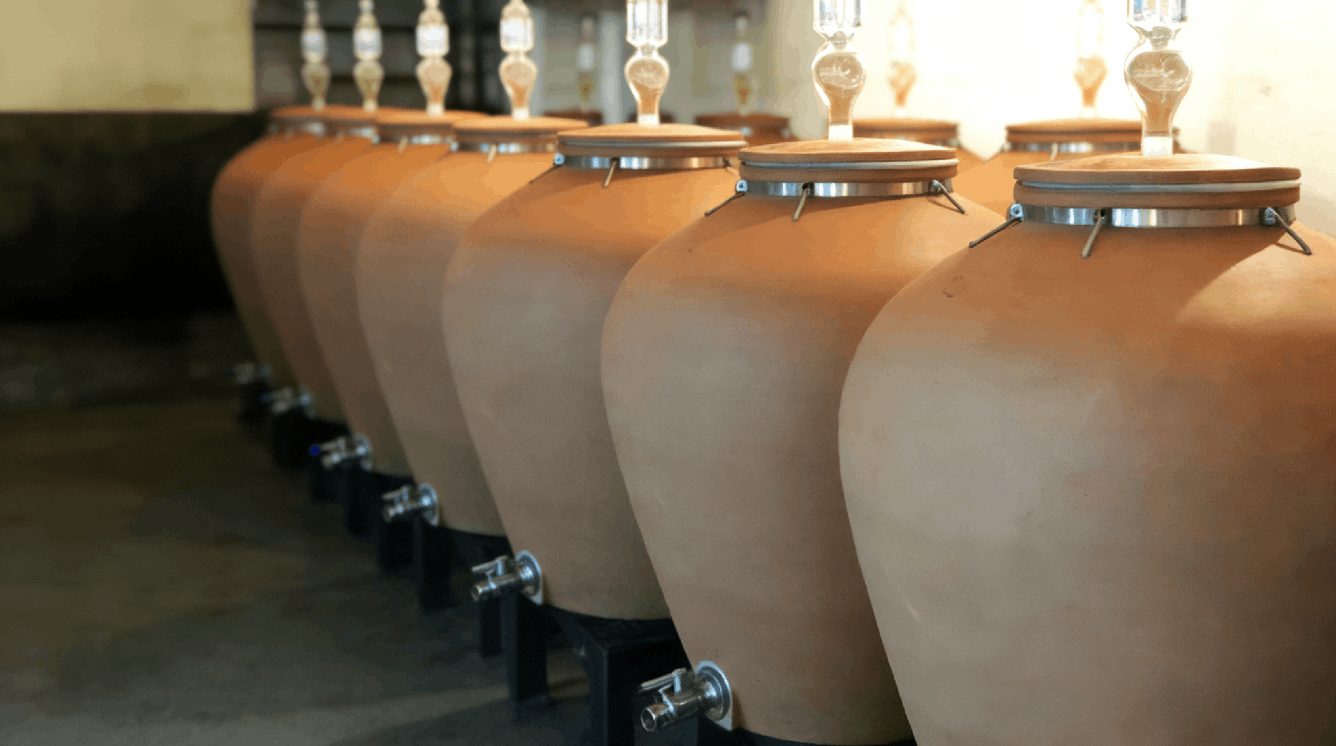

Breathable Clay

Made from carefully selected clay, its micro-porosity allows for a continuous, gentle influx of oxygen, promoting the natural maturation of the wine, developing a smooth texture and complex layers, while preserving the pure essence of the grapes.

Carefully Designed Shape

The streamlined inner walls, whether egg-shaped or pear-shaped, guide the wine to create natural convection, allowing the wine, lees, and oxygen to blend evenly. This eliminates the need for frequent stirring, resulting in a silky texture and harmonious overall feel.

Essential Differences from Other Containers

Compared to mainstream containers, amphorae take a unique “third path”:

Compared to stainless steel tanks: It’s not completely inert, but provides a dynamic micro-oxidation environment, allowing the wine, while remaining pure, to independently develop a more vibrant texture and complexity.

Compared to oak barrels: High-quality amphorae themselves add virtually no additional flavors (such as vanilla or toasty notes). They act more like a neutral guide, focusing on allowing the characteristics of the grapes and terroir to be clearly and authentically expressed.

Therefore, “amphora winemaking” is far more than just a label. It represents a winemaking philosophy: respecting natural processes and using the gentlest methods to guide the wine to reveal its truest and most vibrant self.

The Definition of an Amphora

An amphora is a vessel made from natural clay or terracotta, traditionally used for the fermentation and aging of wine. Unlike modern tanks, amphorae are typically unglazed, allowing the material itself to interact subtly with the wine inside.

Most wine amphorae share several defining characteristics:

Natural clay or terracotta material

Amphorae are made from mineral-rich clay, shaped and fired at high temperatures. This natural material is food-safe when properly produced and does not impart artificial flavors to the wine. You’ll often see terms like clay amphora, terracotta amphora, or wine amphora used interchangeably in modern winemaking.

Egg-shaped or oval form

The iconic egg-like shape isn’t just aesthetic. This rounded structure encourages gentle, natural circulation during fermentation, helping keep lees in suspension without mechanical stirring. That movement can enhance mouthfeel and complexity, especially in amphora wine fermentation.

Porous but controlled structure

Unlike stainless steel, clay is naturally porous. This allows for micro-oxygenation, meaning tiny amounts of oxygen pass through the vessel walls. The effect is subtle but important—it supports stable fermentation and gradual wine development without the flavor impact of oak.

Unglazed interior surface

Most amphorae used for winemaking are left unglazed on the inside. This keeps the vessel neutral, allowing the wine to express grape variety, site, and vintage without added aromas or coatings interfering.

Because of these features, an amphora is often described as a neutral fermentation vessel—one that shapes texture and structure rather than flavor. That’s exactly why many winemakers see amphorae as a middle ground between stainless steel tanks and oak barrels.

In modern usage, you may also hear amphorae referred to as wine fermentation amphorae, clay fermentation vessels, or terracotta wine vessels. While the names vary, the philosophy behind them is the same: letting the wine evolve naturally, with minimal intervention.

A Brief History of Amphorae in Winemaking

Long before stainless steel tanks or oak barrels existed, winemakers were already fermenting and storing wine in amphorae. In fact, for thousands of years, amphorae were the default wine vessel across much of the ancient world.

In ancient Greece and Rome, clay amphorae were used not only for fermentation, but also for aging, transporting, and trading wine across the Mediterranean. Their pointed or rounded bases made them easy to store in ships, while their thick clay walls helped protect the wine during long journeys. At the time, amphora winemaking wasn’t a niche technique—it was simply how wine was made.

So why did amphorae disappear?

As industrialization reshaped winemaking in the 19th and 20th centuries, efficiency and standardization became the priority. Wooden barrels offered easier stacking and predictable flavor influence, while stainless steel tanks brought precision temperature control, hygiene, and scalability. Amphorae, which require skilled craftsmanship and careful handling, slowly faded from mainstream use.

But what was once seen as outdated is now being rediscovered.

Today, amphorae are returning to wineries—not as a romantic novelty, but as a deliberate choice. Modern winemakers, especially those working with natural, organic, or terroir-driven wines, have begun questioning whether total control always leads to better wine. Amphorae offer something different: a way to let wine evolve naturally, guided by material and form rather than technology.

In that sense, modern amphora winemaking isn’t a trend. It’s a return to first principles, informed by centuries of experience and refined with modern quality standards.

Why Are Amphorae Used in Modern Winemaking?

Let’s be honest, when it comes to winemaking containers, most people probably immediately think of oak barrels or stainless steel tanks. But these days, more and more winemakers are starting to use an ancient container—the amphorae. If it were merely a “retro decoration,” this trend would probably have passed long ago. Its true revival is simple: it brings a unique balance to wine, achieving a subtle balance between structure, micro-oxygenation, and flavor neutrality that modern containers struggle to match.

So how does this happen? Let’s examine what magical transformations occur when grape juice is fermented or aged in an amphora.

Micro-Oxidation and Natural Fermentation

One of the most distinctive features of a clay amphora is its natural micro-oxygenation. Because terracotta is slightly porous, tiny amounts of oxygen can pass through the vessel walls over time.

This slow, controlled oxygen exchange supports stable, natural fermentation, especially when working with native yeasts. Instead of forcing fermentation through aggressive temperature control or mechanical intervention, amphorae allow the wine to find its own rhythm.

For you as a winemaker, this often translates into:

● Softer tannin development

● More integrated structure

● A smoother, more textural mouthfeel

Compared to stainless steel fermentation, amphora wine fermentation tends to feel less rigid and more alive, especially during long skin contact or extended aging on lees.

Neutral Flavor Expression

Unlike oak barrels, amphorae do not add external aromas or flavors. There’s no vanilla, toast, or spice influence. What you get instead is a vessel that stays quietly in the background.

This neutrality is exactly why many winemakers choose a wine amphora when they want the grapes—not the container—to speak first.

Fermenting or aging wine in a terracotta amphora allows:

● Grape variety characteristics to remain clear

● Terroir-driven minerality to come through

● Vintage differences to be more transparent

In this way, amphorae sit somewhere between stainless steel and oak—offering structure and evolution without imposing a flavor profile. For producers focused on authenticity, that balance is hard to ignore.

Why Amphora Fits Natural & Organic Wines

Choosing natural or organic winemaking is often not just about selecting a process, but more about choosing a philosophy—minimizing human intervention and allowing the grapes to express the terroir themselves. If you’re still debating whether to use oak barrels or stainless steel tanks, perhaps consider a more “fundamental” old friend: Amphora.

Why is it so perfectly suited to this philosophy? Because Amphora operates almost entirely for minimal intervention. It requires minimal processing, doesn’t rely on heavy filtration, and doesn’t require complex mechanical control. It acts like a transparent and self-disciplined vessel, providing gentle micro-oxidation during fermentation and aging without leaving strong flavor imprints, ultimately allowing the wine to purely and authentically express the vineyard’s character.

In short, choosing Amphora is less about selecting a container and more about choosing a silent, yet loyal, ally for your winemaking philosophy.

● Instead, they encourage:

● Spontaneous fermentation

● Gentle extraction during skin contact

● Slow, natural evolution over time

That’s why amphorae are especially popular for orange wines, skin-contact whites, and expressive, terroir-focused reds. They give you enough structure to guide fermentation, but enough freedom to let the wine become itself.

For many wineries, choosing amphora isn’t about nostalgia—it’s about alignment. The vessel simply matches the way they already want to make wine.

Amphora vs Other Wine Fermentation Vessels Comparison

Choosing a fermentation vessel for wine is a bit like choosing a “growing room.” Each room—whether oak barrels, stainless steel tanks, or amphora—will leave a unique imprint on the wine. Frankly, there’s no absolute “best”; it depends on the kind of wine you want to make and your winemaking philosophy.

The amphora holds its place among these mainstream containers precisely because of its “unassuming” nature. Unlike some containers that try to impose their personality on the wine, it acts as a transparent and inclusive backdrop, allowing the grapes themselves and the natural fermentation process to take center stage.

To better understand the amphora’s unique position, let’s compare it directly with two other familiar containers.

| Fermentation Vessel | Oxygen Exchange | Flavor Impact | Winemaking Style |

| Amphora | Gentle, natural | Neutral | Terroir-driven, natural |

| Oak Barrel | Moderate | Oak-derived aromas | Structured, stylistic |

| Stainless Steel | Minimal | None | Controlled, consistent |

| Concrete Tank | Moderate | Neutral | Clean, textural |

Amphora vs Oak Barrels

Oak barrels have long been associated with premium winemaking, and for good reason. They bring structure, oxygen exchange, and recognizable aromas like vanilla, toast, and spice. When you ferment or age wine in oak, you’re making a stylistic choice as much as a technical one.

Amphorae approach things very differently.

With a wine amphora, you still get micro-oxygenation, but without flavor transfer. There’s no wood character shaping the wine. What develops instead is texture, balance, and a clearer expression of grape and site. For winemakers who feel oak can sometimes overshadow subtle varieties or terroir-driven wines, amphorae offer a more transparent alternative.

You might find amphora fermentation especially appealing if:

● You want structure without oak aromas

● You’re working with delicate whites, orange wines, or terroir-focused reds

● You prefer to let the wine evolve rather than be “designed” by the vessel

In many wineries today, amphorae don’t replace oak—they complement it. Some wines start life in amphora and finish in barrel, while others avoid wood altogether to preserve purity.

Amphora vs Stainless Steel Tanks

Stainless steel tanks are all about control. Temperature precision, easy cleaning, scalability—if consistency is your priority, stainless steel delivers. That’s why it remains the backbone of modern commercial winemaking.

Amphorae, by contrast, invite a different mindset.

When you ferment wine in a clay amphora, you give up some technical control in exchange for a more organic process. The porous walls allow gentle oxygen exchange, and the rounded shape encourages natural circulation during fermentation. Instead of locking the wine into a narrow profile, amphorae allow more flexibility and movement.

This difference becomes especially noticeable when working with:

● Native yeast fermentation

● Extended skin contact

● Wines intended to reflect vintage variation

Compared to stainless steel fermentation, amphora wine often feels less polished but more expressive—textural rather than linear. For producers focused on individuality rather than uniformity, that trade-off can be very appealing.

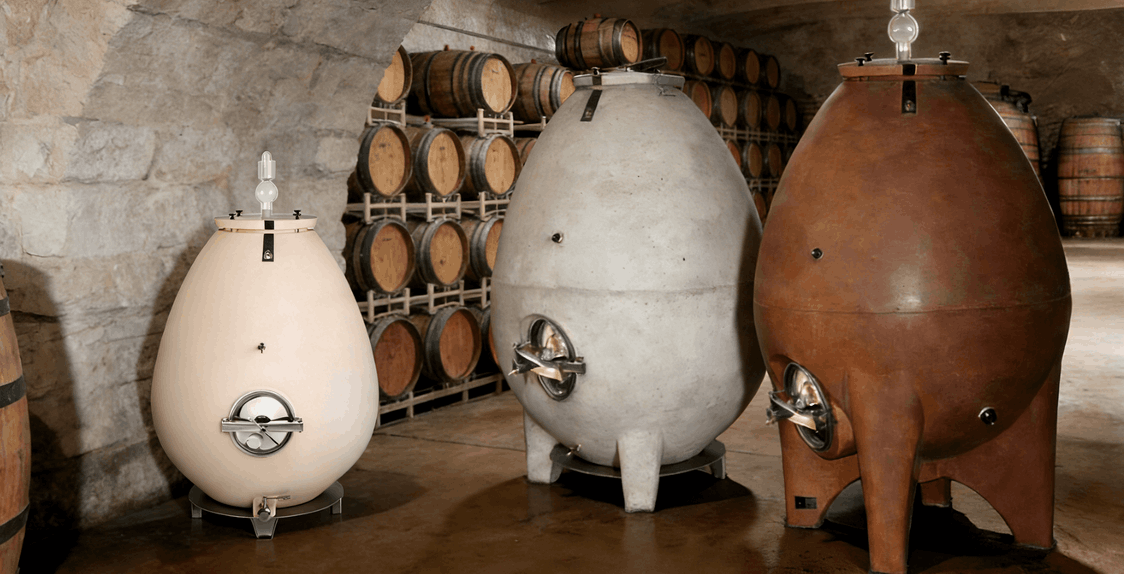

Amphora vs Concrete Tanks

Concrete tanks are often described as amphorae’s closest modern relatives. Like clay, concrete allows micro-oxygenation, and many concrete vessels also use egg-shaped designs to promote natural lees movement.

So where’s the difference?

Material matters. terracotta amphorae are made from natural clay, fired at high temperatures, and shaped with winemaking in mind. The interaction between clay and wine is subtle but distinct, often described as more breathable and responsive than concrete. Amphorae also tend to offer a more traditional, handcrafted approach, which resonates strongly with small-batch and natural wine producers.

Concrete tanks, on the other hand, are typically larger, heavier, and more industrial in feel. They work exceptionally well for wineries seeking consistency at scale, while amphorae shine when precision craftsmanship and individuality are the goal.

If you’re deciding between the two, the question often becomes less technical and more philosophical:

● Do you value handcrafted vessels and small-batch expression?

● Or do you need durability and volume with minimal variation?

What Types of Wines Are Best Suited for Amphora?

Choosing amphora for your wine is essentially making a clear choice: do you want a wine that’s “absolutely standard,” or a wine that’s “more expressive”? If you’re looking for impeccable consistency across vintages, or require complete control, then technical containers like stainless steel tanks might be a safer option.

But if you value whether the wine can reveal a unique texture, more vibrant layers of flavor, and the truest story of the vineyard itself, then Amphora comes to the fore.

Amphora isn’t a universal container, but that’s precisely its value—it knows where its strengths lie. It understands best how to nurture and inspire grapes with “ideas.”

Here are the wine styles where amphora fermentation and aging tend to shine.

Orange Wines

If there’s one style most people associate with amphora winemaking, it’s orange wine—and that connection isn’t accidental.

Extended skin contact is at the heart of orange wine, and amphorae are naturally suited to that process. The rounded shape encourages gentle circulation, keeping skins and lees moving without harsh extraction. At the same time, the porous clay allows slow oxygen exchange, which helps soften tannins and stabilize the wine over long macerations.

For you as a winemaker, this often means:

● More controlled extraction during skin contact

● Better integration of tannin and texture

● A wine that feels layered rather than aggressive

That’s why amphora for orange wine fermentation has become so common among producers looking for structure without heaviness. The vessel supports the process quietly, without adding flavor or pushing the wine in a predefined direction.

Natural Wines

Natural winemaking is less about technique and more about intention. If you’re working with native yeasts, limiting additives, and letting fermentations unfold at their own pace, the vessel you choose matters more than you might think.

Amphorae fit naturally into this mindset. They don’t demand constant intervention, and they don’t impose external character. Instead, they offer a stable, breathable environment where wine can evolve gradually.

Many producers find that amphora fermentation for natural wine:

● Encourages spontaneous fermentation

● Reduces the need for aggressive corrections

● Produces wines that feel alive rather than engineered

There’s also a philosophical alignment at play. Using a handcrafted clay vessel feels consistent with a low-impact, material-conscious approach to winemaking. It’s not about going backward—it’s about choosing tools that respect the raw material.

White Wines

White wines don’t always get mentioned first in amphora discussions, but for many wineries, they’re where the vessel really proves its versatility.

When fermented or aged in amphora, white wines often develop greater texture and mouthfeel without losing freshness. The absence of oak influence keeps aromatics clean, while gentle oxygen exposure helps build structure over time.

This approach works particularly well if:

● You want body without butteriness

● You’re avoiding overt oak flavors

● You’re aiming for site-driven expression

For producers exploring white wine amphora fermentation, the result is often a wine that feels more complete on the palate—rounder, more tactile—without drifting away from varietal identity.

Certain Red Wines

Not every red wine is a natural fit for amphora, and being honest about that actually builds trust.

Amphorae tend to work best with medium-bodied reds where elegance and texture matter more than sheer power. The vessel’s micro-oxygenation can help soften tannins, but it won’t replace the structural impact of oak for wines designed for long, wood-driven aging.

Amphora fermentation or aging often suits:

● Reds focused on freshness and drinkability

● Wines where fruit and acidity are central

● Styles aiming for balance rather than extraction

For these wines, amphora aging for red wine can enhance integration without masking character. Many wineries use amphorae for part of the process, blending amphora-aged wine with barrel-aged lots to achieve the final balance.

Practical Experience

If your production relies heavily on standardized profiles or strong vessel-driven flavors, amphorae may not be the right fit—and that’s okay. Where they excel is in helping wines express place, vintage, and intent with fewer layers in between.

That’s also why amphorae tend to attract a very specific type of winery. And from a manufacturing perspective, that clarity helps everyone make better decisions from the start.

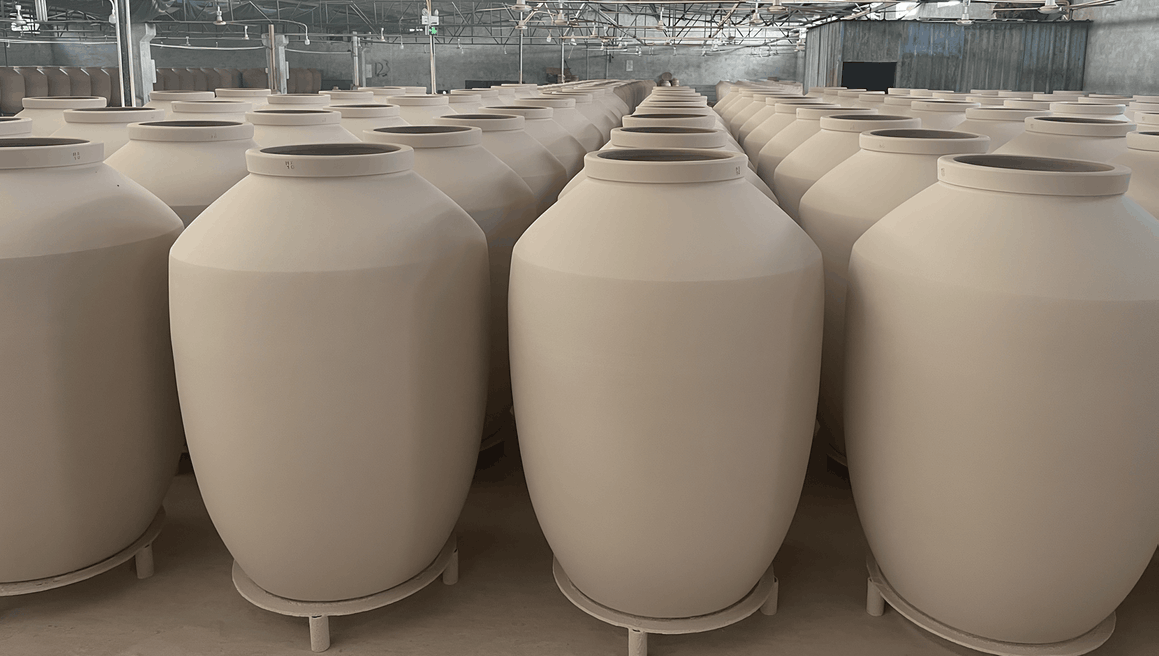

How Is a Wine Amphora Made?

For winemakers and wine merchants, the breathability, durability, and safety of amphora in contact with wine are paramount. Therefore, finding a high-quality amphora maker is crucial.

The quality and craftsmanship of the amphora determine the final quality of the product. While amphoras may not appear particularly striking, understanding their production process reveals why two seemingly similar amphoras can perform drastically differently in the cellar.

Excellent amphora makers typically adhere to strict quality standards and procedures at every stage, from clay selection and testing, clay preparation, shaping, natural drying, firing, high-temperature firing, leak detection, and quality control. Therefore, it all begins with the selection of materials, shaping, and control of each step.

Clay Selection and Material Safety

Imagine the clay used to make amphora as a special vineyard. The quality of this “terroir” directly determines the safety and purity of the final wine. Therefore, you can’t just dig up any clay and use it—truly suitable clay for winemaking must be clean, stable, and “wine-friendly.”

So, what is ideal clay like? First, it must be naturally clean, with a stable mineral composition, and it must withstand the daily close contact with wine. This means that careful selection of raw materials is crucial from the very beginning. Reliable sourcing and rigorous testing are essential steps to ensure that no potentially harmful substances will seep into the wine during the long aging process.

Ultimately, choosing a high-quality amphora is essentially choosing a trustworthy “land” for your wine.

At HEXIN, clay selection is driven by three non-negotiables:

● Natural terracotta clay with stable mineral composition

● Food-contact safety, suitable for fermentation and aging

● Unglazed interiors, so nothing interferes with the wine itself

An unglazed amphora allows direct interaction between wine and clay, which is essential for micro-oxygenation. At the same time, it demands much stricter control of raw materials and firing conditions. There’s no glaze to “hide” imperfections—everything depends on the clay being right from the beginning.

This is why food-safe clay amphora manufacturing isn’t just about materials, but about consistency and discipline at the earliest stage.

Handcrafted vs Industrial Production

How an amphora is formed has a direct impact on its structure and performance.

Handcrafted wine amphorae are shaped gradually, allowing the clay to align and settle naturally. This process creates a more organic internal structure, which helps balance porosity and strength. It also allows thickness to be adjusted according to vessel size and intended use—something industrial molding struggles to achieve.

Industrial production, on the other hand, focuses on speed and uniformity. While it can work for decorative or non-fermentation vessels, it often lacks the fine control needed for amphora wine fermentation, especially at larger volumes.

Two factors matter most here:

● Wall thickness control: too thin, and the vessel risks cracking; too thick, and oxygen exchange becomes limited

● Firing temperature alignment: handmade amphorae are fired with the final use in mind, not just for appearance

A properly made amphora balances these variables so that strength, breathability, and longevity work together rather than against each other.

Firing, Porosity, and Structural Stability

Firing is where an amphora truly becomes a winemaking vessel

The firing curve—how fast the temperature rises, how long it’s held, and how it cools—directly affects porosity and strength. Fire too low, and the amphora remains fragile. Fire too high, and the clay becomes overly dense, limiting oxygen exchange.

For wine amphorae, the goal is controlled porosity:

● Enough micro-pores to allow gentle oxygen transfer

● Tight enough structure to prevent leakage or structural weakness

This balance determines not only how the amphora performs during fermentation, but also how long it can be safely used. A well-fired amphora maintains structural stability through repeated fermentation cycles, temperature changes, and long aging periods.

When done correctly, terracotta wine amphorae can serve wineries for many years, offering consistent behavior and predictable results from vintage to vintage.

Why This Matters for Wineries

For a winery, choosing an amphora isn’t just about size or shape. It’s about trusting that the vessel will behave the same way year after year, without compromising wine quality or safety.

That reliability comes from manufacturing depth, not surface design—and it’s exactly where experienced amphora producers separate themselves from general ceramic suppliers.

Why are Quality Control, Certifications, and Safety so important?

When you bring amphorae into a winery, you’re not just buying vessels—you’re introducing a material that stays in direct contact with wine for months, sometimes years. That naturally raises questions about safety, consistency, and long-term reliability.

These concerns are especially common among European and North American buyers, and they’re reasonable. The good news is that a professionally made wine amphora can meet the same safety expectations as any modern fermentation vessel—when quality control is taken seriously.

Food Contact Safety

Think of a wine amphorae as the “second skin” of the grape. Since the wine will be in direct contact with it for months or even longer, its “food contact safety” is not an option, but a fundamental requirement.

So, how does a safe, wine-specific amphorae achieve this? The key lies in two aspects:

● The material itself: It must use pure, natural clay that is particularly resistant to acidic liquids like wine, remaining stable under prolonged immersion.

● Internal treatment: Its inner walls are typically unglazed. This may seem rough, but it’s crucial—the absence of a glaze eliminates any risk of coatings interfering with natural fermentation or the leaching of potentially harmful substances.

In short, a safe wine amphorae strives for this “original purity.” It uses the most essential materials to provide the safest possible environment for the wine to mature.

For wineries, this means peace of mind:

● No artificial linings

● No hidden surface treatments

● No interaction beyond what the clay itself naturally allows

When amphorae are produced with winemaking in mind, they behave predictably and safely across fermentation and aging cycles.

Material Testing and Verification

Raw materials matter, but testing is what turns intention into proof.

Professional amphora manufacturers carry out material testing to ensure clay composition remains stable and free from harmful residues. This includes checks related to mineral content, firing consistency, and overall suitability for wine fermentation.

From a buyer’s perspective, this level of verification reduces risk. It means the amphora you receive isn’t just visually consistent, but structurally and chemically reliable as well—especially important for wineries working under strict internal quality standards.

This is where the difference between decorative ceramics and certified wine amphora manufacturing becomes very clear.

Export Standards and Compliance

For wineries importing amphorae, compliance with export and international trade standards is just as important as product quality.

A manufacturer experienced in global supply understands how to prepare amphorae for international shipping, documentation, and inspection. That includes proper labeling, packaging, and alignment with common requirements in European and North American markets.

When these details are handled correctly, amphorae arrive ready for use—without delays, confusion, or unexpected compliance issues at customs.

Common Safety Concerns from Buyers

Most buyer concerns tend to revolve around a few practical questions:

● Is the amphora safe for long-term wine contact?

● Will the clay affect wine stability or purity?

● Can the vessel withstand repeated fermentation cycles?

These are fair questions, and they deserve clear answers. A well-made terracotta wine amphora is engineered to handle the physical and chemical demands of winemaking. Its safety and performance come from controlled materials, proper firing, and consistent quality checks—not from assumptions or shortcuts.

For many wineries, understanding this process is what turns initial curiosity into real confidence.

Do You Need an Image Here?

How to Choose the Right Amphora for Your Winery

Once safety and quality are clear, the real question becomes more personal:

which amphora actually fits the way you make wine?

When choosing an amphora for a winery, you’re essentially choosing a long-term partner, not just a container. Every characteristic of the amphora will speak to your final wine.

Finding the “right” amphora hinges on aligning it with your winemaking approach. There’s no universal formula, but a few key ideas can help transform abstract style matching into concrete choices:

Your winemaking philosophy is central

First, clarify whether you’re aiming for precise control and flavor consistency, or whether you prefer a more natural, individualistic expression in your wine. This directly determines the type of “partner” you need.

Consider size and shape

The tank’s capacity and geometry affect the fermentation temperature and the contact area between the wine and the tank walls, thus influencing the extraction of body and flavors. What do you need it for? Whole-chain fermentation or aging?

Focus on materials and craftsmanship

As discussed earlier, the source of the clay, the firing temperature, and whether the inner walls are glazed—these details collectively constitute the amphora’s “personality,” determining its oxygen permeability and the final wine’s texture.

Evaluate practical factors

its weight, ease of handling, cleaning difficulty, and smooth integration with your existing production processes. These everyday details are equally important.

Ultimately, the most suitable amphora is the one that meets your technical requirements, resonates with your philosophy, and seamlessly integrates into your winery’s daily operations.

If you already have a more specific idea of the type of amphora you need, or need to compare the details of different processes, I’d be happy to provide a more in-depth analysis.

Amphora Size and Volume

Size is usually the first thing wineries ask about, and for good reason. Amphora volume affects fermentation dynamics, temperature stability, and how much hands-on management the vessel requires.

Smaller amphorae tend to respond quickly to fermentation activity and temperature changes. They’re often chosen for experimental batches, single-vineyard wines, or styles where close observation matters. Larger amphorae offer more thermal stability and are better suited for consistent production lots.

When choosing size, it helps to think about:

● Your typical batch volume

● Whether the amphora is for trials or core production

● How much cellar space and handling flexibility you have

Searching terms like wine amphora size selection or amphora fermentation volume often reflect buyers already at this stage of decision-making.

Shape and Design Considerations

Amphorae come in different shapes, and those differences aren’t just visual.

Egg-shaped and oval designs encourage natural movement during fermentation, keeping lees gently suspended. More vertical forms can offer a slightly calmer internal environment, which some wineries prefer for aging rather than active fermentation.

Design choices also influence practical details:

● Ease of cleaning

● Stability during fermentation

● How the vessel fits into your cellar layout

Choosing the right shape is about aligning vessel behavior with your workflow, not chasing aesthetics.

Above-Ground vs Buried Amphorae

Some wineries prefer buried amphorae, while others work exclusively above ground. Both approaches can work well, but they serve different needs.

Buried amphorae benefit from natural temperature moderation provided by the surrounding soil. This can be attractive for wineries seeking minimal energy input and very stable fermentation conditions. Above-ground amphorae offer easier access, monitoring, and cleaning—often a better fit for modern cellars.

The choice usually comes down to:

● Climate and cellar design

● How closely you monitor fermentation

● Installation and maintenance preferences

This is also where terms like buried amphora winemaking or above ground wine amphora naturally appear in buyer research.

Custom Amphora vs Standard Models

Standard amphora models work well for many wineries, especially those just starting with amphora fermentation. They’re predictable, proven, and easier to integrate quickly.

Custom amphorae become relevant when your process has specific requirements. That might include tailored volume, wall thickness adjustments, customized openings, or compatibility with existing cellar systems.

Wineries searching for custom wine amphora or OEM amphora manufacturer are often looking for more than a product—they’re looking for a manufacturing partner who understands winemaking constraints.

Matching Amphora Choice to Your Wine Style

Ultimately, amphora selection works best when it reflects your wine style rather than forcing a new one.

If you focus on natural or orange wines, you may prioritize breathability and shape that support skin contact. If your goal is purity and texture in white wines, neutrality and internal movement matter more. For certain reds, integration and balance tend to guide the choice.

The right amphora feels less like an experiment and more like a natural extension of how you already make wine.

One Image Is Enough Here

You don’t need many visuals in this section. One clear, informative image helps buyers visualize decision points without distraction.

Why Work with a Professional Amphora Manufacturer Like HEXIN

Choosing an amphora is essentially choosing the manufacturer behind it. This choice becomes even more crucial when you view the amphora as an integral part of the winemaking process, rather than a one-off experiment. In this case, the manufacturer acts like an absent winemaker—their expertise and understanding subtly participate in your entire winemaking process through every detail of the amphora.

So, what tangible differences does working with a professional manufacturer like HEXIN bring?

Manufacturing Knowledge That Goes Beyond Ceramics

Not every clay vessel producer truly understands wine.

A professional amphora manufacturer works at the intersection of ceramic science and fermentation reality. That means knowing how clay behaves not only in a kiln, but also under months—or years—of contact with wine, yeast, acids, and temperature shifts.

At HEXIN, amphora design decisions are informed by:

● Fermentation pressure and internal movement

● Long-term structural stability under cellar conditions

● How porosity affects oxygen exchange over time

This level of understanding matters if you’re searching for wine amphora manufacturer rather than a general ceramic supplier.

Consistency You Can Rely On, Vintage After Vintage

What’s the biggest fear in winemaking? Unexpected events. Especially when you’re full of anticipation, only to find that this amphora produces a wine with a completely different flavor profile than the previous one. This uncertainty is often the number one challenge many wineries encounter when actually using amphoras.

Therefore, when you choose a professional producer, you’re really buying predictability. Take Hexin, for example. Their commitment to consistent quality means ensuring that every amphora leaving the factory possesses uniform and stable physical characteristics, from the selection of core clays and rigorous recipes to standardized process control throughout the entire process. This minimizes batch variations, allowing you to focus on the art of winemaking rather than dealing with variables introduced by the container itself.

A professional producer controls variables that directly impact fermentation results:

● Clay sourcing and preparation

● Wall thickness tolerance

● Firing temperature curves and cooling cycles

That consistency means the amphora you use this year behaves like the one you’ll use next year. For wineries planning to scale amphora use, this predictability becomes essential.

OEM and Custom Amphora Solutions for Real Cellar Needs

Some wineries know exactly what they need. Others only discover it after a few harvests.

Working with a manufacturer that offers OEM and custom amphora services gives you flexibility without starting from zero every time. Adjusting volume, shape, wall thickness, or openings becomes part of an ongoing collaboration—not a special request.

HEXIN’s role in these cases isn’t just to execute a drawing, but to translate winemaking goals into ceramic reality.

This is especially relevant for buyers searching custom wine amphora supplier or OEM amphora manufacturer for wineries.

Quality Control, Safety, and Export Experience

Frankly, the biggest worry when ordering large amphoras from overseas is often not the amphoras themselves, but the hidden challenges of the “last few kilometers”: Will they be damaged during transport? Are the customs clearance documents complete and compliant? A problem in any link can disrupt your entire brewing season plans.

Therefore, partnering with an experienced professional manufacturer means buying much more than just a product. Take HEXIN as an example; you get a proven “worry-free delivery system.” This system comprises three key pillars:

● Quality Control: This is not just a pre-shipment inspection, but a comprehensive quality control system from clay selection to final firing, ensuring that every amphora is stable, safe, and reliable.

● Safety Assurance: Professional, customized packaging solutions and shipping agreements minimize the risks associated with weeks of sea freight.

● Export Experience: Extensive experience means they can anticipate and handle all compliance documents, customs clearance processes, and logistics tracking in advance, making international shipping transparent and predictable.

Simply put, the advantage of a professional manufacturer is that they transform these complex back-end matters into a reassuring certainty. You can focus all your energy on brewing ideas and confidently leave the “safe delivery” to the experts.

A professional amphora manufacturer understands:

● Food-contact safety requirements for different markets

● Export packaging that protects heavy, fragile vessels

● Documentation needed for EU and North American imports

That experience removes friction from the purchasing process and avoids surprises after the amphora arrives at your winery

Long-Term Partnership, Not Just a Single Order

Amphora winemaking is rarely static. Techniques evolve, preferences shift, and wineries refine their approach over time.

The value of working with a professional manufacturer shows up years later—when you’re adjusting specifications, expanding production, or replacing vessels with confidence that they’ll integrate seamlessly into your existing system.

This is where the relationship moves beyond product and into partnership.

One Image That Supports the Message

Here, a single image reinforces credibility without feeling promotional.

FAQ

1. Is an amphora food-safe for wine fermentation?

Yes, clay amphorae are suitable for brewing wine, orange wine, and other beverages. Compared to oak barrels, stainless steel tanks, or concrete vessels, amphorae allow for a greater expression of terroir and produce a purer taste, making them increasingly popular among winemakers.

2.Does an amphora add clay or earthy flavors to the wine?

No, a well-made amphora remains neutral.properly fired terracotta does not release flavors into the wine. Instead, the amphora influences texture through gentle micro-oxygenation. Any earthy or

3. How is an amphora different from oak barrels or stainless steel tanks?

Unlike oak, it doesn’t add aroma or tannins. Unlike stainless steel, it allows controlled oxygen exchange. This balance makes amphorae ideal for winemakers who want structure and texture without flavor interference.

4. Are amphorae difficult to use or maintain in a winery?

Amphorae require thoughtful handling and cleaning, just like any fermentation vessel. Once winemakers understand filling, temperature behavior, and sanitation, amphorae often become one of the most intuitive tools in the cellar.

conclusion

You’re choosing far more than just a container; you’re choosing a long-term partner deeply involved in your winemaking process. This partner’s “personality”—shaped by its materials, craftsmanship, and the maker’s expertise—will be directly reflected in the style of your wines.

Therefore, finding the right partner is crucial. If you’re seriously considering incorporating amphora fermentation into your winemaking philosophy, whether it’s your first attempt or optimizing an existing process, collaborating with an expert who truly understands wine and can translate that understanding into a consistently reliable product is often the clearest path to success.

This is precisely where the value of our conversation lies. If you’d like to further explore how to select or customize the most suitable amphora solution for your winery, contact our engineers, and we’re ready to begin this conversation.

Discuss Your Amphora Project

Looking to bring authenticity and unique character to your wine? Discuss your amphora project with us. An amphora is more than a vessel—it’s a long-term choice that shapes how your wine evolves in texture, purity, and expression.

Share your wine style and production goals, and we’ll guide you through selecting the right clay vessel to match your vision. Let’s create something meaningful, together.