Why Wineries Choose Amphora Fermentation Today?

Today, for many wineries striving for authenticity and uniqueness, the choice of fermentation vessel has gone beyond mere technical considerations, becoming a key expression of their core winemaking philosophy.

If you are exploring amphorae, perhaps you are also considering: How to find a balance between control and letting go? How to preserve the purity of the grape variety to the greatest extent? How to produce wines that truly reflect the terroir, rather than the winemaker’s intervention?

The resurgence of amphora fermentation is a response to these profound questions. It is not a fleeting trend, but a thoughtful solution chosen by visionary winemakers worldwide to achieve these goals.

Why Fermentation Vessel Choice Matters More Than Ever

Changing Winemaking Philosophies

In modern wineries, the precise definition of winemaking is undergoing a transformation. It is no longer synonymous with absolute control over every step of the process, but rather allows the grapes, natural yeasts, and the fermentation process itself to evolve naturally within a carefully controlled environment.

This shift in philosophy is making the choice of fermentation vessels more crucial than ever. The vessel is no longer merely a passive container; it has become a fundamental element of flavor expression and a core winemaking tool. Its material, shape, and characteristics profoundly participate in and shape the final character of the wine.

If you work with:

● native or spontaneous fermentations

● organic or biodynamic fruit

● vineyard-driven styles

then your fermentation vessel is no longer a neutral container. It actively shapes how the wine evolves.

Amphorae support this mindset by offering structure without interference. They guide fermentation rather than forcing it.

Market & Consumer Expectations Today

Today’s wineries not only need to produce excellent wines but also operate in a market that places a high value on transparency and authenticity.

Consumers want to know how the grapes are grown and how the wine is made. The fermentation vessels you choose are a crucial chapter in telling this “terroir story,” directly influencing consumers’ perception and trust in the authenticity, craftsmanship, and brand philosophy of your product.

Consumers increasingly ask:

● How was this wine made?

● What makes it different?

● Why does it taste the way it does?

Amphora fermentation provides a credible, non-marketing-driven answer.

It connects material, process, and outcome in a way that feels honest—especially for wineries focused on small lots, terroir expression, and long-term identity rather than volume.

What Makes Amphora Fermentation Technically Unique

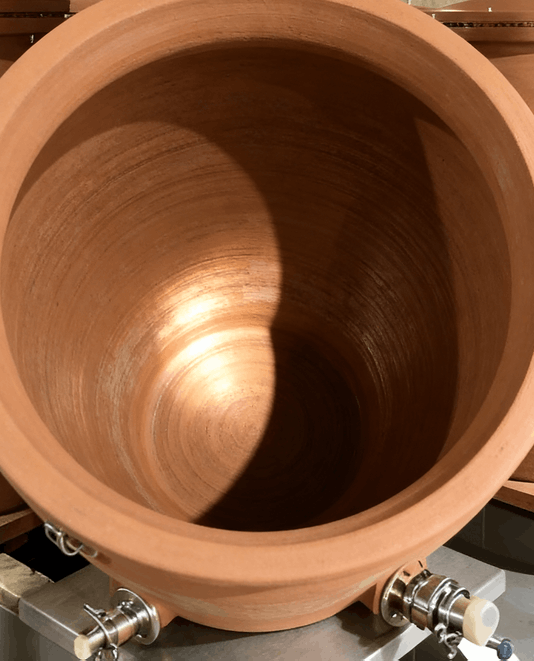

Natural Micro-Oxygenation: How Terracotta Behaves Differently

Terracotta amphorae are naturally porous. Unlike stainless steel, they allow gradual oxygen exchange throughout fermentation and aging.

Unlike oak, however, this oxygen comes without flavor transfer.

The result is a controlled, steady micro-oxygenation that:

supports yeast activity

Amphora unique micro-oxygenation and stable temperature control create a more active fermentation environment with less metabolic stress for natural yeast, which is the core technology behind its ability to promote yeast activity.

softens tannins

Amphora continuously provides a gentle micro-oxygenation environment, which effectively promotes the natural polymerization and softening of tannins in the wine, resulting in a rounder and smoother taste. This is its unique technological advantage.

stabilizes structure

Amphora unique micro-oxygenation process, which guides the stable polymerization of phenolic compounds in the wine, thereby creating a more compact and rounded body with excellent aging potential, is one of its core technologies.

preserves varietal purity

Amphora inert nature means it doesn’t introduce any additional flavors, while its micro-oxygenation softens the texture, preserving the pure fruit aromas and terroir characteristics of the grape variety to the greatest extent when shaping the wine.

From a Manufacturer’s Perspective

At HEXIN, the micro-oxidation effect of our clay amphorae is not accidental.

By precisely controlling key parameters such as the clay composition, wall thickness, and firing temperature, we ensure that each amphora provides a precise and controllable micro-oxidation environment for specific wine styles.

Thermal Stability During Fermentation

The thermal stability during the fermentation process is not only related to the maximum temperature reached, but also to the smoothness of its rise and fall.

Amphora’s excellent insulation properties effectively buffer external temperature fluctuations, providing the yeast with a more stable and less stressful metabolic environment.

Terracotta’s thermal mass helps buffer rapid changes, allowing fermentation to progress more evenly. This is especially valuable when working with:

● native yeast

● long, slow fermentations

● aromatic whites or skin-contact wines

Manufacturing Insight

By adjusting vessel thickness and volume, we help wineries achieve the thermal behavior best suited to their fermentation approach—without relying solely on external temperature control.

Why are vessel shape & structural design so important?

Why Shape Matters in Amphora Fermentation?

The spherical or egg-shaped design of the amphora is not accidental.

This shape promotes natural convection of the liquid inside the vessel, optimizing the uniformity of temperature and substance distribution, and effectively managing the cap of solids, thereby improving the overall efficiency of fermentation and the quality of the wine.

The internal geometry of an amphora influences:

● convection currents during fermentation

● how lees settle

● how wine moves naturally inside the vessel

Egg-shaped and rounded amphorae encourage gentle circulation, reducing the need for mechanical intervention.

Flat-bottom or poorly designed vessels, by contrast, can lead to uneven lees compaction and extraction challenges.

HEXIN Design Approach

HEXIN’s amphora design philosophy prioritizes function above all else, rather than simply adhering to traditional forms. We begin by thoroughly understanding your fermentation and aging goals, then translate scientific principles into precise internal curves and structural designs.

Based on this philosophy, we ensure that the shape, wall thickness, and porosity of each amphora directly serve a specific purpose: to realize your specific vision for wine texture, micro-oxygenation levels, and flavor development, transforming the physical vessel into an extension of your winemaking philosophy.

The clay source & firing process determine the quality of the amphora

Why Not All Terracotta Amphorae Are the Same

“Clay” itself is a broad concept; for winemaking, the specific origin, mineral composition, and firing process of the clay are crucial. These variables directly affect the porosity and micro-oxidation characteristics of the amphora, ultimately shaping the unique character of the wine.

Different clay compositions influence:

porosity

The porosity of the amphora is determined by its clay composition, which directly controls the rate and extent of oxygen exchange and is a core physical property influencing the micro-oxygenation effect and the final style of the wine.

oxygen transmission rate

The clay composition directly determines the oxygen transmission rate of the amphora, thereby precisely controlling the degree of micro-oxygenation and stylistic development of the wine during fermentation and aging.

thermal behavior

The composition and structure of the clay directly determine the thermal conductivity and insulation properties of the amphora, which affects the temperature buffering capacity and overall stability during the fermentation process.

long-term durability

The mineral composition of the clay and the firing process not only determine its physical strength but also affect its resistance to corrosion from substances such as tartaric acid. This directly relates to the lifespan and stability of the amphora during long-term and repeated use.

The Role of Firing Temperature

Firing temperature determines how open or closed the clay structure becomes:

too low → excessive porosity

If the firing temperature of the amphora is too low, its structure will not be fully vitrified, resulting in excessive porosity.

Influence:

This leads to a rapid and difficult-to-control rate of oxygen exchange, potentially increasing the risk of over-oxidation or microbial contamination, thus affecting the stability and purity of the wine.

too high → reduced oxygen exchange

If the firing temperature of the amphora is too high, the clay will become excessively vitrified, leading to a significant reduction in its porosity.

Influence:

This will result in a slower rate of oxygen exchange, potentially affecting the natural softening of tannins and the development of flavors in the wine, thus weakening the unique micro-oxygenation advantages of the amphora.

HEXIN Manufacturing Perspective

We select clay sources and firing profiles deliberately, matching material behavior to the wine’s intended development—rather than producing one “generic” amphora for all uses.

Flavor, Texture & Wine Expression

Neutral Flavor, Maximum Transparency

Amphorae do not add oak aromas or metallic sharpness. Instead, they provide a quiet environment where fruit, site, and fermentation character remain intact.

This neutrality is why amphora fermentation is increasingly chosen for:

whites seeking tension and clarity

For white wines that aim for tension and freshness, temperature-controlled stainless steel tanks are the ideal choice. They maximize the preservation of pure fruit aromas and crisp acidity, preventing oxidation.

orange wines with textural depth

The amphora is the ideal vessel for producing orange wines with a rich texture. Its micro-oxygenation properties allow for the natural development of rounded tannins, a silky texture, and complex flavors during skin-contact fermentation.

reds where elegance matters more than oak structure

For red wines that prioritize elegance over oak structure, amphorae are a key tool in achieving this goal. They provide controlled micro-oxygenation, effectively softening tannins and enhancing textural complexity while avoiding the overpowering oak flavors.

How Does the Amphora Shape Influence It Texture?

Well-designed amphorae allow lees to remain active without aggressive stirring. Over time, this contributes to:

● integrated texture

The unique egg-shaped or spherical design of the amphora promotes natural convection of the wine, allowing the lees to remain evenly suspended, which is a crucial physical basis for achieving a harmonious and silky texture.

● natural roundness

The streamlined inner walls of the amphora guide the gentle movement of the wine, promoting delicate contact with the lees and micro-oxygenation. This is key to giving the wine a naturally rounded, rather than rough, texture.

● subtle complexity

The gentle convection facilitated by the amphora shape allows the lees and the wine to interact fully, slowly releasing substances that add complexity and layers of flavor.

From a design standpoint, internal curvature and bottom structure are critical here.

Amphora vs Stainless Steel, Oak & Concrete

When Amphora Is the Right Tool

Amphora fermentation works best when your priority is:

● expression over imprint

● texture over power

● balance over intervention

When It Is Not

Amphorae are not a universal solution.,high-volume production, heavy oak styles, or rapid throughput may favor other vessels.

Most wineries find the greatest value in combining amphorae with stainless steel, oak, or concrete—using each where it excels.

Amphora Fermentation in Real Winery Operations

Cleaning, Hygiene & Maintenance

A common concern—and a valid one.

Modern terracotta amphorae can be designed with surface treatments that improve cleanability while preserving functional porosity.

With appropriate protocols, amphorae integrate seamlessly into contemporary winery hygiene systems.

Durability & Long-Term Use

Well-crafted amphorae are not short-term consumables, but rather brewing assets that can be passed down for decades.

Their durability lies in the selection of high-quality clay and precisely controlled firing techniques, which together ensure that the vessels possess the structural strength to withstand tartaric acid corrosion and temperature stress, providing wineries with a stable long-term return on investment.

Custom Terracotta Amphorae for Modern Wineries

A truly custom amphora derives its value from breaking free from the limitations of “standard products.” From the clay composition and wall thickness to the firing process, it should be precisely designed and adjusted to achieve your unique winemaking goals.

At HEXIN, we collaborate directly with winemakers to define:

● vessel capacity

● shape and wall thickness

● surface finish

● fermentation or aging purpose

This ensures each amphora fits both your wine style and cellar workflow.

Explore our Terracotta Amphorae to see available designs and customization options.

Why Wineries Choose HEXIN as Their Amphora Partner ?

The winery chose HEXIN as their amphora partner, not only because they trust our containers, but also because they value our deep understanding of winemaking. We combine scientific knowledge and craftsmanship to provide complete solutions, from custom design to technical support.

We bridge:

material science and winemaking logic

HEXIN combines cutting-edge materials science with a clear winemaking philosophy. We don’t just supply amphorae; we ensure that their material properties (such as porosity and thermal performance) precisely serve your specific vision for wine style and terroir expression.

traditional craftsmanship and modern requirements

HEXIN deeply understands the essence of traditional amphora production while designing to meet the stringent demands of modern wineries for precision, hygiene, and consistency. We ensure that every amphora embodies ancient wisdom while conforming to contemporary winemaking standards.

traditional craftsmanship and modern requirements

HEXIN deeply understands the essence of traditional amphora production while designing to meet the stringent demands of modern wineries for precision, hygiene, and consistency. We ensure that every amphora embodies ancient wisdom while conforming to contemporary winemaking standards.

Our amphora solutions offer ample internal space and a well-designed structure for easy installation, monitoring, and cleaning and maintenance. This design, combining traditional reliability with modern convenience, allows it to be flexibly integrated into various winemaking environments, from boutique wineries to large-scale production facilities.

manufacturing precision and cellar reality

HEXIN’s manufacturing precision ensures that key parameters such as wall thickness and porosity are highly consistent for every amphora. This is not only about quality, but also about seamlessly adapting to the precise temperature control, hygiene management, and efficient layout of modern wine cellars.

We have fully considered cellar space and workflow in the design, making it easy to move safely, place securely, and maintain daily. This deep consideration of practical applications allows HEXIN amphorae to reliably serve a wide range of production environments, from traditional to highly modernized.

Our role is not to tell you what to ferment—but to help you ferment the way you intend.

Amphora Fermentation: Frequently Asked Questions

1. Are terracotta amphorae suitable for all wine styles?

They are best suited for wines where purity, texture, and expression are priorities.

2. Are amphorae lined or unlined?

Both options exist, depending on fermentation goals and maintenance preferences.

3. How long do terracotta amphorae last?

With proper care, several decades.

4. Can amphorae be customized for my winery?

Yes—size, shape, and surface treatment can all be tailored.

5. How do amphorae compare to concrete eggs?

Both offer micro-oxygenation, but terracotta provides a more organic material interaction depending on clay and firing.

Conclusion

Choosing the right amphora is essentially selecting the most precise vessel for your winemaking philosophy and terroir expression. It concerns the final texture, complexity, and authenticity of the wine, and is a crucial technical decision that connects the vineyard to the glass.

If standard solutions cannot fully meet your unique vision for flavor development and winemaking control, HEXIN is ready to help. Contact us to receive customized solutions based on our professional expertise, and let’s explore the unlimited possibilities of amphora winemaking together, helping you achieve even more exceptional wine expression.