What is wine amphorae – A Complete Guide

Today, the amphora is a favorite and sought-after winemaking vessel among professional winemakers.

Made from natural clay fired at temperatures exceeding 1200°C, it possesses remarkable properties: strong, porous, and breathable.

Compared to oak barrels, amphora winemaking offers a rounder, more sober flavor and a greater expression of terroir.

In this guide, we’ll explore all the key aspects of this wine amphora—from its definition, materials, production techniques, main types, maintenance, and uses.

What is wine amphora?

Wine amphorae are clay vessels used for fermenting and aging wine, tracing their origins to ancient civilizations across Georgia, Greece, and Rome.

Unlike modern containers, these traditional pots are typically egg-shaped Conical, cylindrical, etc. and made from porous clay, allowing minimal oxygen exchange during the winemaking process.

Today’s amphorae for winemaking combine traditional forms with contemporary engineering, creating vessels that maintain historical integrity while meeting modern hygienic and production standards.

Materials and Manufacturing

Natural clay

Amphora used for winemaking is still made of natural clay. Its main characteristics are:

● Clay’s most fundamental characteristic is its plasticity and ease of shaping.

● Firing at high temperatures makes it hard, durable, and permanently fixed.

● Clay is naturally porous and breathable.

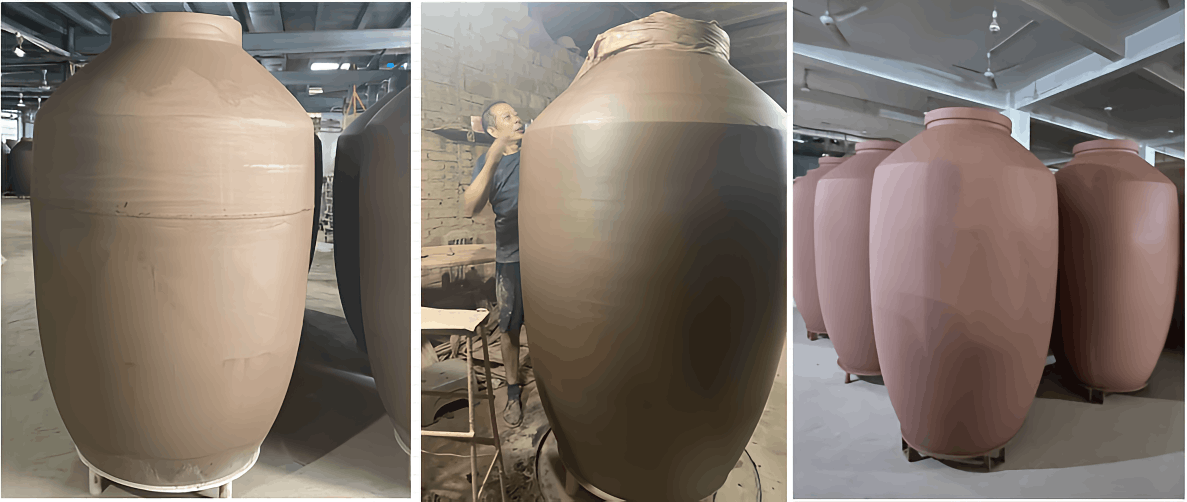

Manufacturing Process

The wine amphora production process is as follows:

● Clay Selection: Selected natural clay undergoes further processing.

● Clay Making: Molded clay strips are formed using clay making equipment.

● Wrought Finishing: Artisans meticulously hand-polish the pots.

● Wrought Finishing: Artisans meticulously hand-finish the pots, preserving their traditional character.

● Glazing: Glazed using an automatic glaze sprayer.

● Drying: Finished amphora are dried in a drying room.

● Firing: Fired in a modern tunnel kiln at high temperatures (typically over 1200°C).

● Testing: Finished products undergo quality testing for porosity and structural integrity.

Wine Amphora Manufacturing Types

From ancient times to the present day, amphorae have evolved over a long period of time. Yet, they remain highly sought after in the winemaking community today.

As a professional manufacturer in China, we can customize wine amphorae in any shape.

By Origin and Style:

● Georgian Qvevri: The original amphora, buried underground

● Italian Anfore: Typically above-ground vessels

● Spanish Tinajas: Often larger and more conical in shape

● Modern interpretations: Contemporary designs with technical improvements

By Origin and Style:

● Georgian Qvevri: The original amphora, buried underground

● Italian Anfore: Typically above-ground vessels

● Spanish Tinajas: Often larger and more conical in shape

● Modern interpretations: Contemporary designs with technical improvements

By Size and Capacity:

● Experimental sizes (50-200 liters) for testing and small batches

● Production sizes (200-1000 liters) for commercial winemaking

● Custom configurations tailored to specific winery needs

Why Choose Amphorae?:Features and Advantages

Amphora Advantages:

● Micro-oxygenation: Porous clay minimizes oxygen exchange, naturally softening tannins.

● Thermal Stability: Clay’s insulating properties maintain a consistent temperature.

● Mineral Influence: Specific clay compositions enhance the texture and complexity of wine.

● Neutral Environment: Unlike oak, clay does not impart additional flavors.

Quality Improvements:

Wines produced in amphorae typically demonstrate:

● Enhanced aromatic complexity

● Improved texture and mouthfeel

● Better integration of tannins

● Greater aging potential

● Unique mineral characteristics

Maintenance and Care: Ensuring Longevity

How to Clean an Amphora:

● Initial seasoning with water and wine mixture

● Between batches: Hot water and mechanical brushing

● Periodic deep cleaning: Steam treatment and natural sanitizers

● Storage: Complete drying between uses to prevent microbial growth

Long-term Maintenance:

● Regular inspection for hairline cracks

● Monitoring for clay degradation

● Proper handling to prevent impact damage

● Environmental control to prevent thermal shock

Practical Applications in Modern Winemaking

Fermentation Uses:

● Skin-contact white wines (orange wines)

● Whole-cluster fermentations

● Extended maceration programs

● Natural wine production

Aging Applications:

● Post-fermentation maturation

● Blending component development

● Pre-bottling integration

● Experimental wine projects

FAQ: Addressing Common Amphora Questions

1.How long do amphorae typically last?

With proper care, quality amphorae can last decades. The oldest continuously used vessels in Georgia have been in service for over 50 years. Regular inspection and careful handling are key to longevity.

2.What’s the cost comparison between amphorae and oak barrels?

While initial cost is higher than standard barrels, amphorae have a much longer lifespan. A quality 100-liter amphora costs $2,000-$3,000 but can last 20+ years, while oak barrels require replacement every 3-5 years at $1,200-$1,500 each.

3. Can amphorae be used for all wine varieties?

While particularly successful with aromatic whites and elegant reds, amphorae work well with most varieties. The key is understanding how each grape variety responds to clay aging and adjusting winemaking protocols accordingly.

4.How does cleaning compare to stainless steel tanks?

Amphorae require more manual cleaning but no chemicals. The process involves hot water, steaming, and mechanical brushing. While more labor-intensive, many winemakers find the results justify the additional effort.

5. What training is needed for staff?

Transitioning to amphora winemaking requires understanding clay’s unique properties. We recommend starting with small lots, detailed record-keeping, and potentially consulting with experienced amphora winemakers.

Implementation Guide: Getting Started with Amphorae

For New Users:

1. Begin with a single small vessel (50-100L)

2. Select a familiar variety for your first trial

3. Maintain detailed notes on the process

4. Compare results with control lots in other vessels

For Commercial Wineries:

1. Develop a phased implementation plan

2. Train key staff in amphora-specific techniques

3. Create dedicated space and equipment

4. Establish cleaning and maintenance protocols

The Future of Amphora Winemaking

The amphora revival represents more than a trend—it’s a fundamental reconnection with winemaking’s roots. As research continues to validate traditional practices, we’re seeing:

● Improved vessel designs incorporating modern materials

● Better understanding of clay-wine interactions

● Growing consumer appreciation for amphora-aged wines

● Increased availability of quality vessels at various price points

For winemakers seeking to create wines with unique character and authentic expression, amphorae offer a proven path to achieving remarkable results that stand apart in today’s competitive market.

Whether you’re exploring small-scale experimentation or planning commercial production, understanding wine amphorae provides the foundation for successfully incorporating this ancient technology into your modern winemaking practice.

Contact Us Now to Learn More About Wine Amphorae

As a professional wine amphorae manufacturer and supplier in China, we are committed to providing wineries and winemakers with distinctive wine amphorae. We support OEM and ODM customization.

Fill out the form to contact our manufacturing experts today and we’ll make your dream a reality!