Your Supply Partner for OEM Korean Fermentation Crocks: Volume + Quality

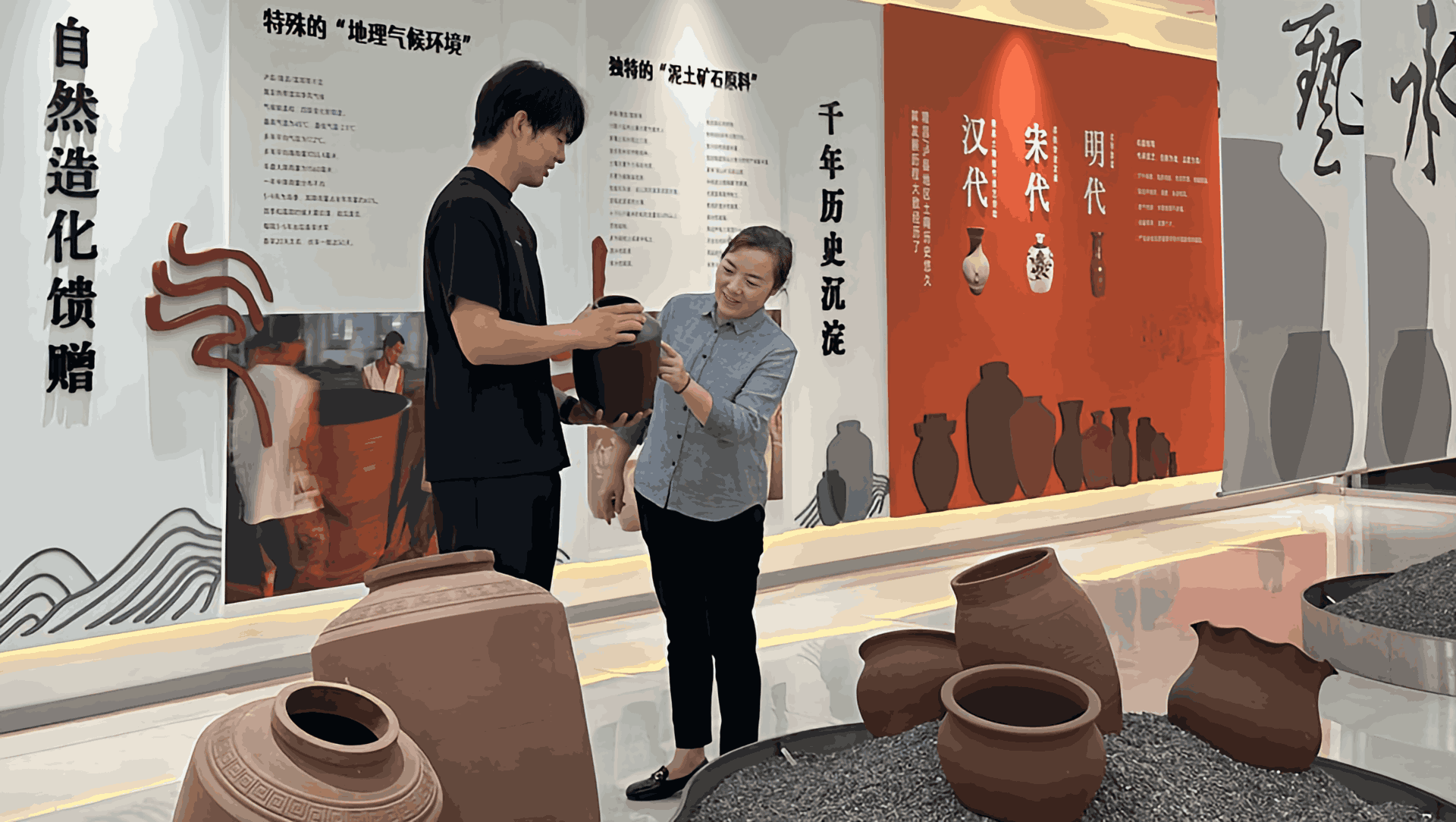

In the globalized fermentation product market, finding a Korean fermentation crocks OEM partner that provides both large-scale production and exquisite craftsmanship is a very difficult task.

In the face of the surge in consumer demand for traditional fermentation methods, as a brand, it is necessary to have a comprehensive and in-depth understanding of its partners, whether it is manufacturing processes, terracotta factory scale, quality control, and service support, all of which must be authentic and trustworthy. Here are some things you need to pay attention to when choosing your ideal OEM fermentation crocks supplier.

Manufacturing Capability&Quality Assurance

Authentic Production Capabilities

The combination of nearly 50 years of craftsmanship and modern quality control by China’s top OEM fermentation crocks manufacturer. We use natural clay materials from specific mining areas to make each Korean fermentation crocks, with a porosity suitable for fermentation.

Unlike traditional fermentation containers made of other materials, our traditional Weng vessel retains the necessary microporous structure to ensure that gas exchange is crucial for successful fermentation. At the same time, we support large-scale production through modern kiln (intelligent temperature controlled tunnel kiln) technology.

Scalable Quality Assurance

When evaluating OEM fermentation crock suppliers, examine their quality control processes at volume. Our facilities implement:

● Raw material testing for consistency in clay composition

● Monitoring of firing temperatures across all production batches

● Individual inspection of each commercial kimchi crock before packaging

● Load testing for durability in shipping and handling

Customization Capabilities for Brand Differentiation

Design Flexibility

Beyond standard fermentation crocks, the right partner should offer comprehensive customization:

● Custom sizing from individual kimchi containers to large restaurant fermentation crocks

● Brand-specific color development for glazes

● Private label packaging and branding options

● Modifications to traditional designs for specific market needs

Material Innovations

While maintaining traditional authenticity, forward-thinking manufacturers offer:

● Lead-free glaze formulations meeting international safety standards

● Reinforced clay bodies that maintain porosity while improving durability

● Thermal-shock resistant formulations for varied climate markets

● Lightweight designs that reduce shipping costs without compromising function

Stable supply capacity and logistics support

Consistent Output Capacity

A true volume partner should demonstrate:

● Monthly production capacity of 20,000+ units across various sizes

● Consistent lead times regardless of order volume

● Multiple production lines dedicated to different product categories

● Established relationships with raw material suppliers ensuring uninterrupted production

Global Logistics Experience

Successful commercial fermentation crock suppliers must have:

● Experience shipping fragile ceramic goods internationally

● Packaging solutions proven to minimize breakage during transit

● Relationships with reliable freight forwarders specializing in ceramic goods

● Warehouse facilities for quality inspection and consolidation before shipment

Partnership Beyond Production

Technical Support and Market Knowledge

The difference between a supplier and a partner lies in added value:

● Fermentation expertise to advise on product development

● Market intelligence on successful product features across regions

● Technical documentation for your customers on crock usage and care

● Collaborative approach to solving production challenges

Sustainable and environmentally friendly manufacturing

Modern buyers increasingly value:

● Eco-friendly production methods with water recycling systems

● Energy-efficient kiln technology reducing carbon footprint

● Fair labor practices and safe working conditions

● Transparent supply chain from clay source to finished product

Building Your Brand With the Right Partner

Choosing an OEM partner for Korean fermentation crocks requires balancing traditional authenticity with modern business needs. The ideal supplier delivers not just products, but partnership – helping you build your brand with quality products that honor fermentation traditions while meeting contemporary market demands.

Why Partner With Us:

● Decades of experience in traditional and modern terracotta manufacturing

● Capacity for large orders with consistent quality

● Comprehensive customization services

● Competitive pricing without quality compromise

● Dedicated international client support teams.

Whether you’re launching a new line of traditional kimchi crocks or expanding your existing fermentation product offerings, our combination of artisanal knowledge and industrial capacity ensures your brand receives the quality and reliability your customers deserve.